Premium Portable Laser Cleaning Machines

Follow The link

Our high Energy laser non-destructive cleaning machine adopts a new generation laser and an upgraded control system and trajectory algorithm independently developed by Lasermach® and a high-end galvanometer.

The unique design makes the laser cleaning effect remain uniform under hand-held conditions.

Contaminants are effectively removed and the metal substrate appears white and bright. Even if the same position is cleaned multiple times, there is still no damage and the metal color is as new.

Especially suitable for silicone rubber product mold cleaning and stainless steel weld cleaning.

It can be used for non-destructive cleaning and removal of various metal substrates, such as stainless steel, mold steel, aluminum alloy, titanium alloy and other surfaces.

PhotonClean Trident Series Laser Cleaning Machines

The only Laser Cleaning Machine with Engraving and Marking function integratged

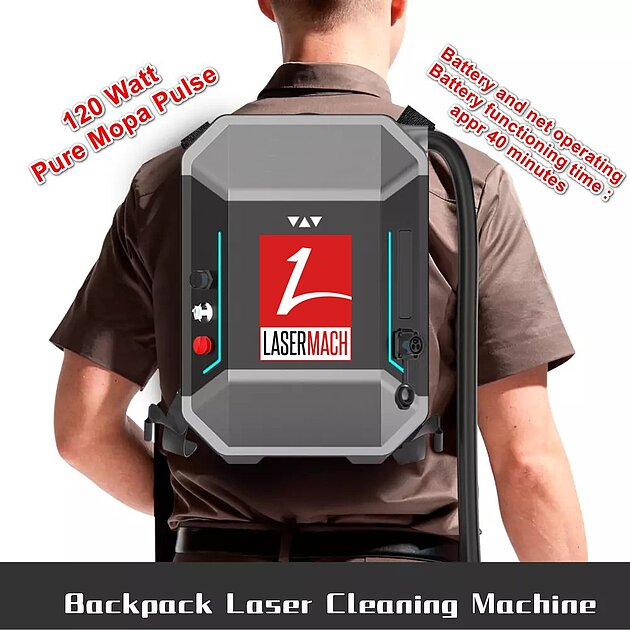

Backpack Trident laser cleaner

Laser Cleaning - Laser Marking - Laser Engraving in one portable lightweight machine

Portable Trident Series Laser Cleaner

220- 320 - 500 Watt

High precision MOPA laser cleaning Machines

New Trident Series: Laser Cleaning AND laser marking AND laser engraving in one machine!

The only laser cleaning machine with laser marking and laser engraving inluded

Super compact and easy transportable Laser Cleaning Machines with integrated Engraving and Marking function ·

First Laser Cleaning machine on the market with marking and engraving.

3 Machines in 1

TRIDENT SERIES

Traceability has become a major issue in the industrial sector. As the density of information required for traceability increases, manufacturers must improve the way information about their products is stored.

A better tracking of products can provide significant cost savings, improve efficiency and ensure compliance to your clients’ request for an improved traceability system.

Laser direct part marking is the ideal solution for many industrial applications.

Laser direct part marking (LDPM)

Metals have a tendency to get dirty, to corrode and to have unexciting surface finishes. To solve these issues coatings may be applied to metals. Aluminum gets anodized, steel gets painted and stainless steel gets passivated. In all of these instances, you may have to inscribe something on these coatings or remove them altogether and that can be done by laser.

Markings may take different forms such as 2D and 1D barcodes, a brand logo or a simple alphanumeric serial number. In order to answer to the growing demand for industrial traceability, numerous metal marking techniques such as laser direct part marking (LDPM) has been developed.

Laser direct part marking has many advantages here is the most commonly quoted:

- It uses no consumable

- it is easy to automate

- It requires only light maintenance.

Lasermach laser technology experts have established, for its clients in the primary metal and the automotive industries, the parameters for perfect laser marking on a lot of metals under different conditions.