Upgrade the Welding Process, Don't replace your Robot

Laser Modernization: Advancing quality, speed, and cost reduction of existing MIG/MAG and TIG robotic Welding Systems, Without Robot Replacement.

Laser Welding Upgrading Kits from PhotonWeld for TIG/MIG/MAG Welding Robots

Many exisiting industrial laser workstations and robotized TIG/MIG/MAG welding cells retain a solid mechanical foundation, yet their control electronics, safety modules, or welding sources no longer align with current manufacturing requirements. This leads to reduced process stability, limited functionality, quality issues, too low production speed and increasing operational costs.

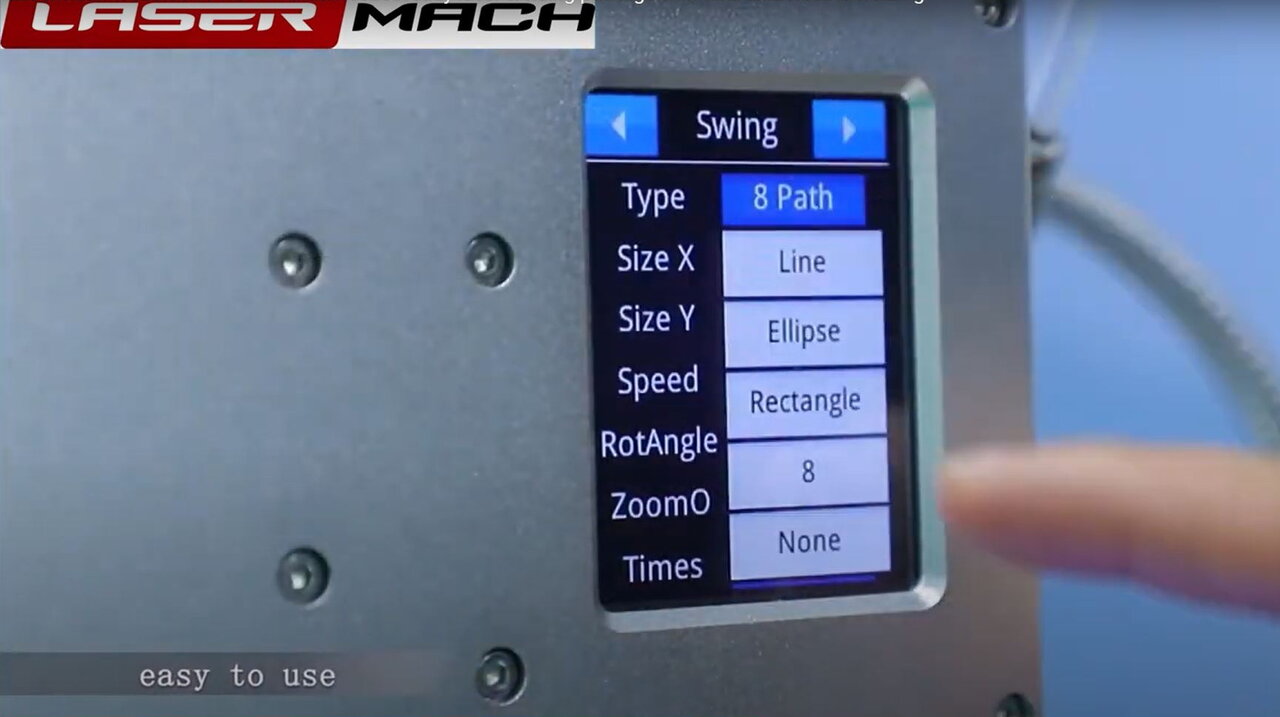

PhotonWeld provides perfect retrofit solutions that modernize existing MIG/TIG/MAG welding cells without the need for full system replacement. The upgrade involves integrating new-generation laser sources, ultra modern and efficient laser welding heads, advanced control and safety electronics, optional real-time monitoring capabilities, optional real time seam tracking and enhanced automation interfaces.

Our modernizations deliver:

⚙ drastic increased production speed

⚙ Much better energy efficiency and drastic lower energy cost

⚙ improved process accuracy and repeatability;

⚙ higher operational reliability;

⚙ extended equipment lifetime;

⚙ compliance with modern industrial standards;

⚙ avoidance of costly complete system renewal.

⚙ Huge cost reduction

Limitations of MIG/MAG and TIG Welding

As industrial automation grows, robots are increasingly used in both simple handling and advanced manufacturing processes. Welding remains one of the most common robotic applications, typically performed using MIG/MAG, TIG, or hybrid technologies. Although established and widely adopted, these methods impose inherent limitations in welding speed, heat input, fixture requirements, and overall process stability.

MIG/MAG welding can reach speeds of up to 3 m/min on thin metals, yet it generates a wide heat-affected zone (HAZ), increasing the likelihood of thermal distortion. This requires rigid and costly fixtures to maintain part geometry. In addition, MIG/MAG produces significant metal spatter, which contaminates torches, sensors, and cables, and often demands manual post-processing such as grinding.

TIG welding, while valued for its precision and aesthetic seam quality, operates at much slower speeds - up to 0.7 m/min - and still produces a considerable HAZ. TIG applications also depend heavily on expensive tooling to control distortion.

Laser Welding as the Perfect Option and solution

PhotonWeld Laser Welding Upgrade: Laser Welding Using Your Existing Robot

Robotic laser welding combines the high speed of MIG/MAG with the precision and cleanliness of TIG. Despite its advantages, adoption is often constrained by the requirement to purchase an entirely new robotic system, significantly increasing investment costs. To address this challenge, we developed different retrofit solutions that transforms existing MIG/MAG or TIG robotic cells into lperfect adapted aser welding cells by replacing the original torch with a dedicated laser welding torch. This approach preserves the robot—typically the most expensive component—while substantially enhancing welding performance. Laser welding can reach speeds of up to 15 m/min on thin metal alloys. Due to its high travel speed, the heat-affected zone is dramatically reduced, nearly eliminating distortion and minimizing fixture requirements. In many cases, standard clamps are sufficient. The process ensures stable parameters, minimal spatter, and a clean seam profile that often requires no additional finishing.