THE WORLD-CLASS LASER WELDING MACHINE MANUFACTURER

The Best or Nothing!

PhotonWeld PRO-Series: Innovation meets Tradition

Laser Welding Machines with the sensational feeling and the looks of Arc Welding Machines

PhotonWeld-Pro-Series: Revolutionary Handheld Laser Welding System for Fabricators

PhotonWELD TM handheld laser welding machines are easy to learn, simple and fast to set up and provides consistent high-quality results across a wide range of materials and thicknesses

PhotonWeld A-PRO - THE POWER OF EFFICIENCY

Rugged and rain proof laser Welding Machine - Making 'Smart' More Simple

-> Cooled with double circuit HEAT PUMP: Most efficient on the market

-> Running from 220V Mono Phase

-> Running in the Rain : IPX3 Standard

-> Running continuously 100% Duty 24/24 - 7/7

-> Running from -30°C till +60°C ambient temperature : the only one on the market

-> Ultra Portable : from 38 to 48 kg

-> Lightest laser welding torch in the market : <600g

-> Super Energy saver compared to other laser welding machines

-> 3 Button Control: the most simple on the market

NEW !!! PhotonWeld Master-Pro Series Named "THOR"

Premiere 2025 09 : Schweissen & Schneiden Expo Essen (Booth 9200 Hall 9)

PhotonWeld Master-PRO - THE POWER OF EFFICIENCY

New Rugged and rain proof laser Welding Machine - Making 'heavy welding' More Simple

-> Running continuously 100% Duty 24/24 - 7/7

-> Running from -30°C till +60°C ambient temperature: the only one on the market

-> Cooled with double circuit HEAT PUMP: Most efficient on the market

-> Running from 380V Tri Phase

-> Running in the Rain: IPX3 Standard

-> Ultra Portable: from 52 to 68 kg

-> Lightest laser welding torch in the market <600g

-> Super Energy saver compared to other laser welding machines

-> 3 Button Control: the simplest on the market

The Advantages of Laser Welding Over Arc Welding

Laser welding is an extremely precise, fast and high energy efficient welding technique.

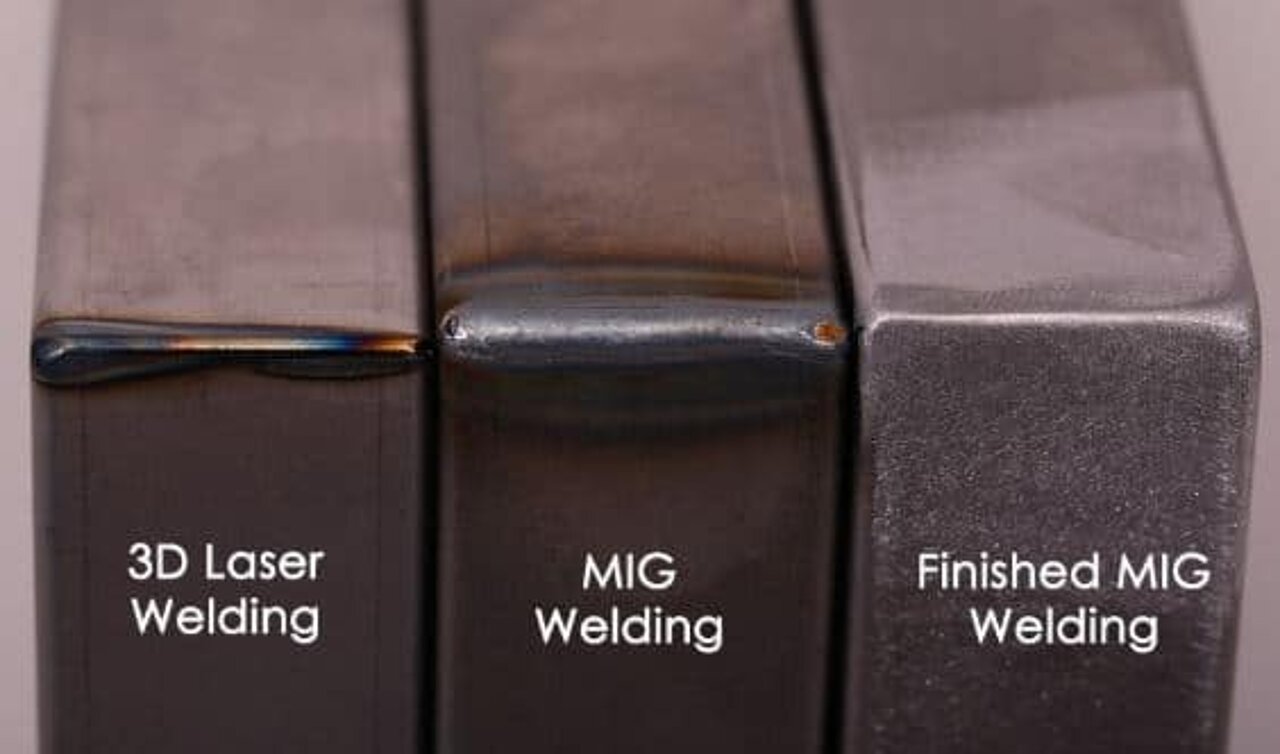

There is no tool that can be used in such a diverse way as the laser. With it, fine weld spots with a diameter of 0,1 mm can be created very quickly, as well as deep weld seams of several meters long. With minimal deformation, very fine seam geometries with a large depth-to-width ratio can be created. Lasers weld materials with a high melting temperature, as well as others with high thermal conductivity. Thanks to their reduced fusing, and easily controllable short fusing time, they can even join materials that otherwise cannot be welded or can only be welded with difficulty. If necessary, additional materials can be used. Product designers and process engineers considering laser welding as an alternative to more conventional types of welding, such as MIG-MAG or/and TIG arc welding, will find each has its plusses and minuses. But for most applications laser welding is a cleaner, more precise, and more controlled method of welding and is especially much faster and better controllable.

Stunningly simple, extraordinarily effective

It is obvious that this machine has been developed by Welding specialists for the best welders

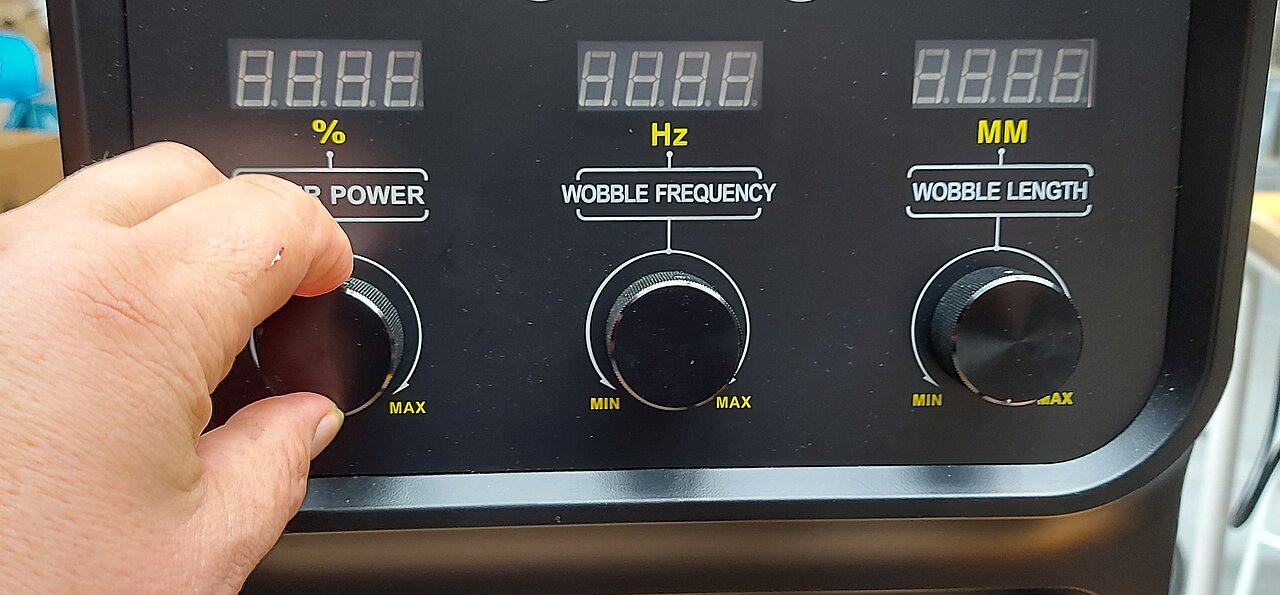

THE IMPORTANCE OF FEEDBACK IN SWITCHES AND DIALS

User interfaces have always been a vital aspect of the working experience. The look, feel and method of interface interaction is one way that machine manufacturers separate themselves from competing machine makers. In the industry electromechanical switches play a large role in defining the touch, feel of interface actuation.

As the gateway to a user interface, a switch or dial solution must have a desirable appearance and feel. To achieve this result, we worked closely together with major automotive switch manufacturers to optimize aesthetics, ergonomics and performance. The result is that even with gloves on, you feel the clicks in the rotary dials. This selection dials do give you the feedback when turning. You do even not have to look to know how much you did set the parameters up or down.

PhotonWeld A-Pro series of handheld laser welders always puts customers' needs first and provides customized solutions for the difficulties in copper welding applications.

Laser energy density and resistance to high reactive energy are the keys to continues welding.

The PhotonWeld A-Pro series handheld welding machine adopts an integrated design. It's unique integrated welding gun design has strong anti-return light capabilities and can continuously weld high-reflective materials without generating heat or shutting down.

The PhotonWeld A-Pro series of handheld welders has rich welding modes. Its pulse welding mode has a maximum welding frequency of up to 50KHz . In the high-frequency welding mode, the small spot laser can penetrate copper to form a weld while minimizing the thermal impact. .

PhotonWeld A-Pro series handheld welding adopts 14um "small core diameter" technology, the spot diameter is less than 40um , and the laser energy density is 300% higher than that of traditional laser welding machines. Even without wobble welding, it can effectively reduce porosity, which can be said to be a powerful tool for copper welding. In addition to reducing porosity, "small core diameter laser technology can also increase laser utilization by making the beam energy more concentrated, reduce the reflection of laser by copper or Aluminum and extend the service life of lenses and handheld welders.

Lasermach continues to carry out technological innovation and research and development, continues to delve into customer scenarios, actively collects user feedback, conducts scientific research and application transformation of laser technology based on the difficulties and pain points that end users really need to solve, and uses the power of innovation and technology to create product value. Provide truly valuable solutions and establish Lasermach Laser’s own differentiated competitiveness.

VIDEO: Laser Welding is .... OUFFFF!

Independant laser welding machine test by "soudeurs 2.0" - click on video to view

LASER WELDING MADE SIMPLE !!

Most Easy controllable Laser welding machine, 3 rotary buttons for the 3 most important functions

Innovative Control Concepts with gives you the feeling of using a standard Welding Machine

The only Synergetic Laser welding controller that works and feels like a normal welding machine

FOOLPROOF OPERATION !

MAKE IT SIMPLE

Step 1: Select your material on the screen

Step 2: Select your thickness to weld on the screen

Step 3: Select if you are welding with or without wire infeed

Start Welding!

==>Thats all it needs to make a perfect laser Weld

NEW Synergic Control in Laser Welding : constant quality and rapid welding

Very simply, synergic control in a Laser welding machine refers to a machine that automatically sets the welding parameters, according to material to weld.

Human control alone is no longer enough in precision industrial processing where instruments such as welding machines are used. Only highly specialised workers can continue using manual welding machines, but this entails a high cost to companies where many high-skill welders need to be employed in the production line. An unskilled welder could make mistakes and slow down the whole work process, inevitably causing delays in deliveries and a rise in costs.

Today, the issues due to human error in welding are much lower thanks to technologies that make these machines synergic.

A synergic laser welding machine helps the worker not make mistakes, work quickly and with always-high quality standards. Our PhotonWeld A-Pro most advanced digital laser sources for welding does have selectable memories where all the settings are ready to go, depending on the material to be welded, the thickness of the material used, and if there is infeed wire chosen.

With these synergic welding machines, perfect beads can be made, quickly, even with less specialised welders.

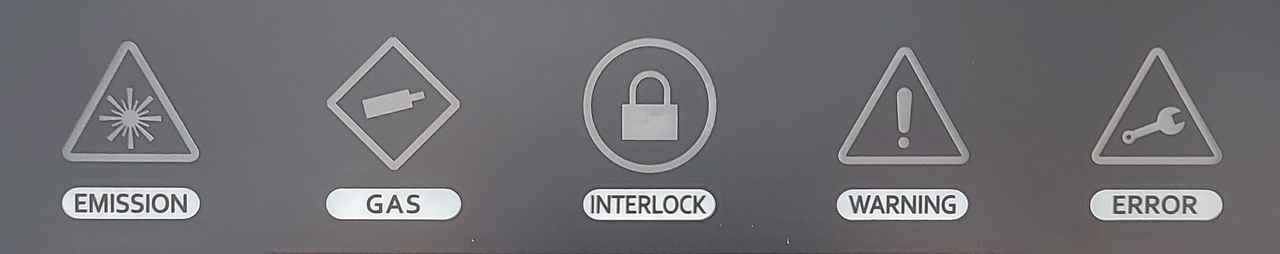

Very visible and bright Alarmlights on the front screen

See immediatly when gas pressure is low or when the laser is on

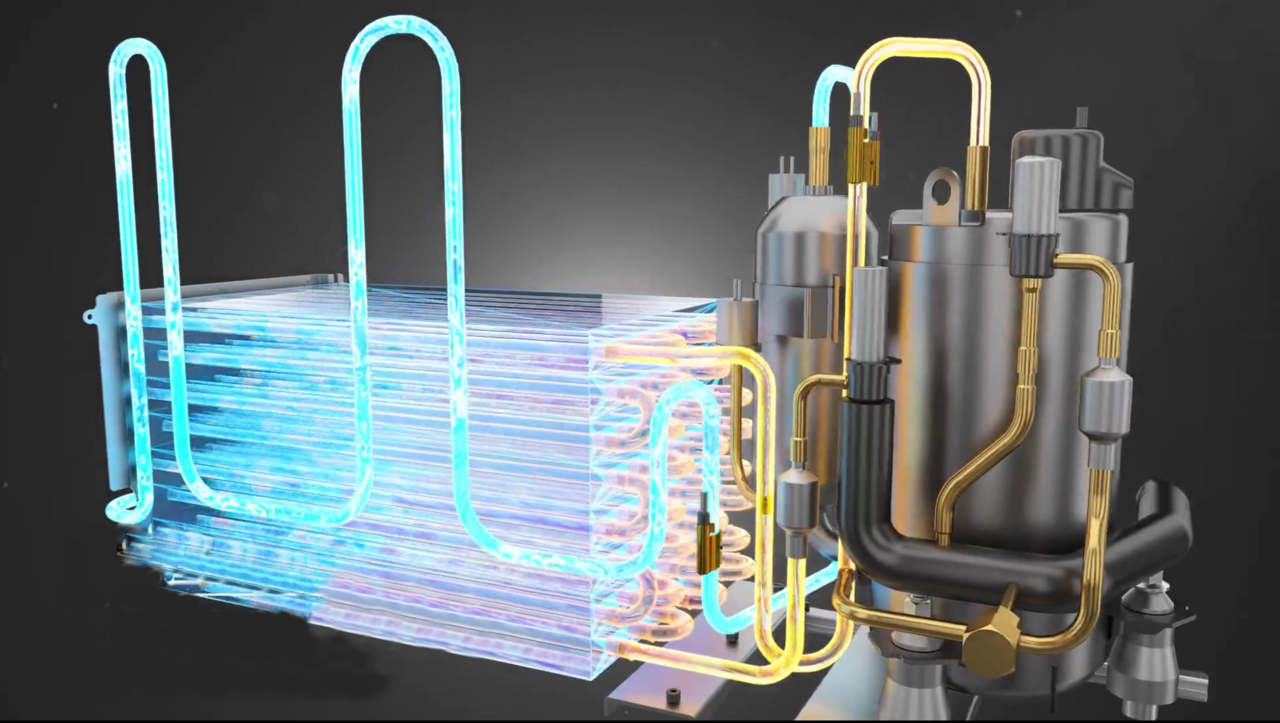

SmartCool i-drive Inverter Compressor

Taking efficiency even further

Laser Welding Machines with liquid gas injection cooling direct into the lasersource

by Economical Heat Pump with invertor driven compressor

We do inject cold into the laser before the laser source even can heat up, while all other competitors have to wait till the heat comes out.

UNBEATABLE EFFICIENCY, IN EVERY LOAD CONDITION

The advantages of the ecolener formula represents the no-compromise solution of the new range.

Able to run Continuos at 100% with 60% less energy consumption compared to other laser welding Machines

Maximum reliability, wide operating range, continuous capacity modulation, class A efficiency. The result is a unit that focuses on efficiency in all load conditions, overcoming the limitations traditionally imposed by the other cooling systems

Our High efficient Heat pump with invertor drive reduces drastic the electrical consumption

Heat pumps are a mature technology that is much more energy efficient than any other cooling or heating technology

Ultra light and flexible torch

Only 595 gramm included the cable coupling

Super high speed Wobble head technology

2-D dynamic programmable beam motion

The concept of the 2-D dynamic beam motion or lineair wobble head technology. Independent control of the amplitude and frequency of the oscillation is achieved through a high speed servo controller, allowing more flexibility in stabilizing the keyhole melt during the welding process.

Stability of the keyhole melt is a critical factor when laser welding dificult highly reflective materials such as copper and aluminum. This is partly due to the tendency to spatter, and in the case of some aluminum alloys, a high level of porosity due to the viscosity and surface tension of the melt when using more traditional laser welding techniques. Recent studies have shown the reduction or elimination of these problems with the beam wobble technique, including a recent systematic study with and without fller wire on automotive aluminum alloys.

Overall, the wobble head technique allows for better temperature management of the part. Because the beam passes near any given point of the weld multiple times, the ramp in temperature and cooling rates is slower than in traditional laser welding, which helps eliminate defects and manage spatter.

In addition, this welding technique is compatible with typical welding accessories such as assist gas ports and coaxial nozzles that enable plume suppression and can help control spatter; techniques that are not readily compatible with the scan heads used in remote welding.

In addtion to stabilizing the keyhole melt and reducing porosity in the subsequent weld, the beam wobble technique has proven valuable for alleviating the part-fit requirements for laser welding. Using one of the programable shapes (infnity in this case) and optimizing the amplitide and frequency of the oscillation, an increase in the acceptable seam gap of three times that achieved in conventional laser welding has been demonstrated.

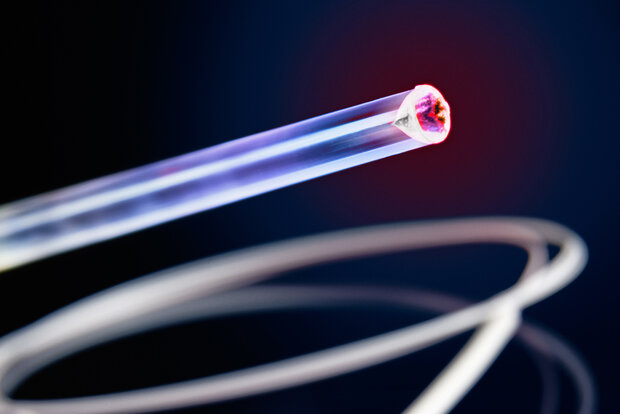

A compact and air-cooled fiber connector design including integrated collimating optics.

THE LIGHTEST AND SMALLEST HANDHELD WELDING TORCH IN THE INDUSTRY

The welding torch design is super compact and very ergonomic, light, high comfortable to hold and easy to operate with even great acces to confined spaces.

- 595 grams

- 270mm x 230 mm total length total height

- Ergonomic Design

- Status Indicator

- Auto centering of Laserbeam after crash

- Robust construction

- Well balanced and high comfortable

- available with a selection of nozzle tips to optimize different joint types.

- Single Trigger Operation

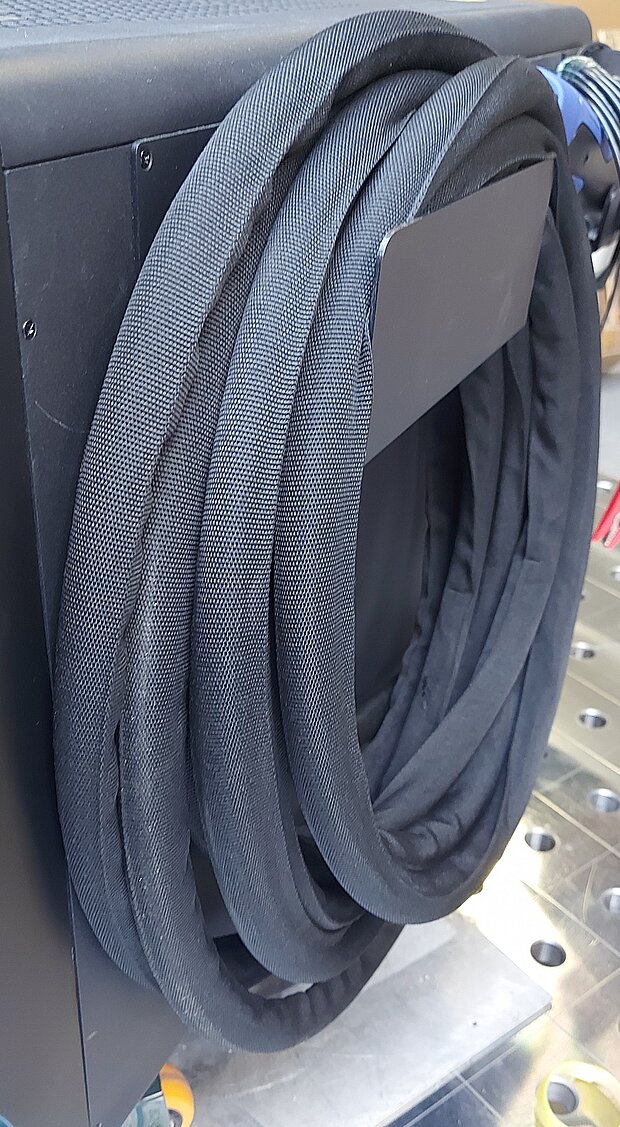

- QCS Fibre Optic Cable triple protected

- 10 meter fiber cable to reach any corner of a big part

- Dual safety light build-in

- Auto wire feededing by continious push, auto wire retracting by short push

The use of collimated QCS interface greatly reduces the size and weight of the welding torch,only 595g. The optical design is perfectly matched with the QCS output head, the transmission efficiency is high, and the heat generation is small. In addition, the torch has a built-in swing function that allows the operator to consistently and safely perform high-quality welds throughout the day with dual safety light buttons.

TESTING PhotonWeld A-PRO Series

Intensive Drip and Spray Water Testing following IPX3 protocol

THE RAIN ROOM

Our very own weather machine. This sophisticated testing facility is designed to simulate a wide variety of rain conditions. Using specially engineered rain nozzles strategically positioned in the chamber, we test a Machine waterproof design in conditions that range from light drizzle to wind-driven rain.

Oscillating tube

The oscillating tube is made of stainless steel equipped with multiple special spray nozzles. The oscillating movement range of the spraying tube is reaching to ±60° in this test.

Drip Tray

The drip tray is made of stainless steel, and the drip holes are evenly distributed.

Fast adjustable and changeable Nozzle

Weld always with the perfect nozzle and the exact focus length

- Adjust the focus length of your welding nozzle in seconds without rotation of the nozzle tube

- Change your nozzle, and only the top of the nozzle tube in a flash

- Never lose time with adjusting of totated nozzle

- Custom made nozzles are easy to make

- different nozzle-ends available for specific use

- changeover from nozzle in less than 20 seconds

Safety First: Build-in Safety indicator

Safety indicator on torch for activation or stop of the laser beam

PhotonWeld A-PRO: Full CE Safety certified Handheld Laser Welding Machines

Equiped with all CE requested Safety accesoiries connections as standard

- Laser beam Emission indicator + external emission warning indicator control

- Remote interlock connector with Multi safety interlocks:

- Nozzle contact interlock

- Door contact (external) interlock

- Foot pedal (dead’s men pedal) interlock ready (optinal),

- Hardware Key control lock

- Internal (and external - optional) double wired emergency stop

- Failsafe start-stop control

WE HOLD SAFETY OF PEOPLE IN HIGH ESTEEM!

Avoid A broken Fiber Cable

Multiple fiber cable protections

- Triple protection around the glass fiber cable

- High protective stainless steel Anti bending unit at cabinet exit avoid cracking of the fiber cable when pulling on the torch cable

- Fiber Cable exit from the torch on the machine is mounted at the side of the machine to avoid accidental bending when pushing the machine against another object or the wall

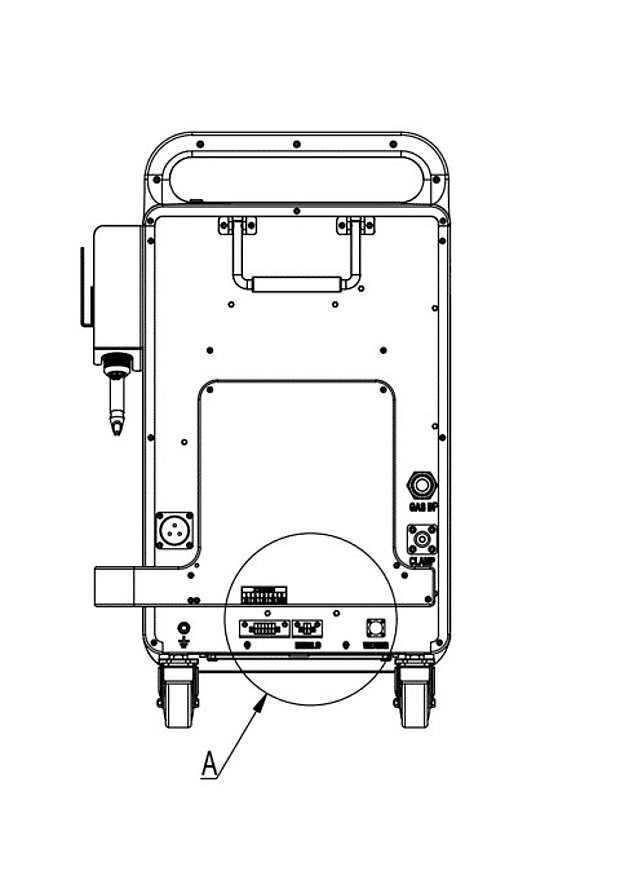

PhotonWeld A-Pro T-Series

Available with Optional COBOT ROBOT interface

Start your automation with your own existing Robot.

Connect our Photonweld A-Pro T-Series to any Robot and Cobot.

Very simple and easy interface.

No need for high level programming!

Need only 5 contacts from your robot or cobot.

Safety note

Please note though, that laser welding does have some unique hazards which need to be accounted for when considered as a welding process. A provision of a welding enclosure should also be made when using, testing or having demonstrations at your place!

For this reason, the demonstrations are by preference not available on site unless having an adequate protection.

Demonstrations and tests will need to take place in Our Demo Center