Lasers are Dangerous to Eyes

Experts classify laser emitting devices according to the wavelength and power of the beams they generate, and, consequently on how much danger they pose to users.

Because laser beams are so tightly focused, they are quite dangerous. Even a small amount of laser light can cause permanent eye injury, burning the retina, and therefore government regulations control exposure.

Most of the danger from laser light comes from the heat, but at some wavelengths (not the wavelength we use:1076nm IR) there are also dangerous photo-chemical effects. With high-powered lasers, even reflected diffuse light can damage eyes. However, most of the danger from laser beams comes from its coherence, concentrating an intense amount of energy upon a tiny spot of the retina, destroying photoreceptor cells.

Infrared lasers, mostly used in our handheld laser Welding Machines, pose a particular hazard.

Because they cannot be seen, they do not trigger the eye’s blink reflex.

Powerful lasers in the 400-1400 nm range penetrate the eyeball and heat the retina. At other wavelengths, the cornea and lens absorb the energy, leading to cataracts or burns. The retina has no pain receptors, so exposed workers often don’t even know they’ve been injured until they detect the resulting vision problems.

Offering Laser Safety Glasses - laser safety spectacles - and Laser Safety Goggles

When buying laser safety glasses and goggles, be sure to select the laser glasses to block or attenuate the appropriate wavelength range and Optical Density (OD).

We are offering a full product line of laser protection glasses which protect the eyes from Class 4 laser systems.

All Lasermach's Safety eye-wear meet or exceed ANSI Standards for the appropriate laser safety systems and

is special adapted to laser welding and laser cleaning

Our Selected Safety eyewear for laser welding

Good Eyes Safety Requires Wearing Protective Eyewear When Using Welding or Cleaning Lasers

Glasses and goggles are clasified by its Optical Density (OD).

That is the base-0 logarithm of the attenuation factor by how much the filter reduces the beam’s power. For example, glasses with OD 2 reduce the laser beam by a factor of 100 (10²), glasses with OD 3 reduce the laser beam by a factor of 1000 (10³), ... Required eyewear must reduce the OD to a power below the maximum permissible exposure.

You must also make certain the lenses and frames of the glasses are physically strong enough to take a direct hit from the laser without breaking. Therefore, you must also take into account their damage threshold. The OD and light wavelengths the glasses protect against must be printed on the frames or in the glass.

Also, laser operators must wear the glasses specifically for that laser’s wavelength. Laser glasses for another machine, with a beam of a different wavelength, are not safe even if their OD is just as high or their laser frequency is different.

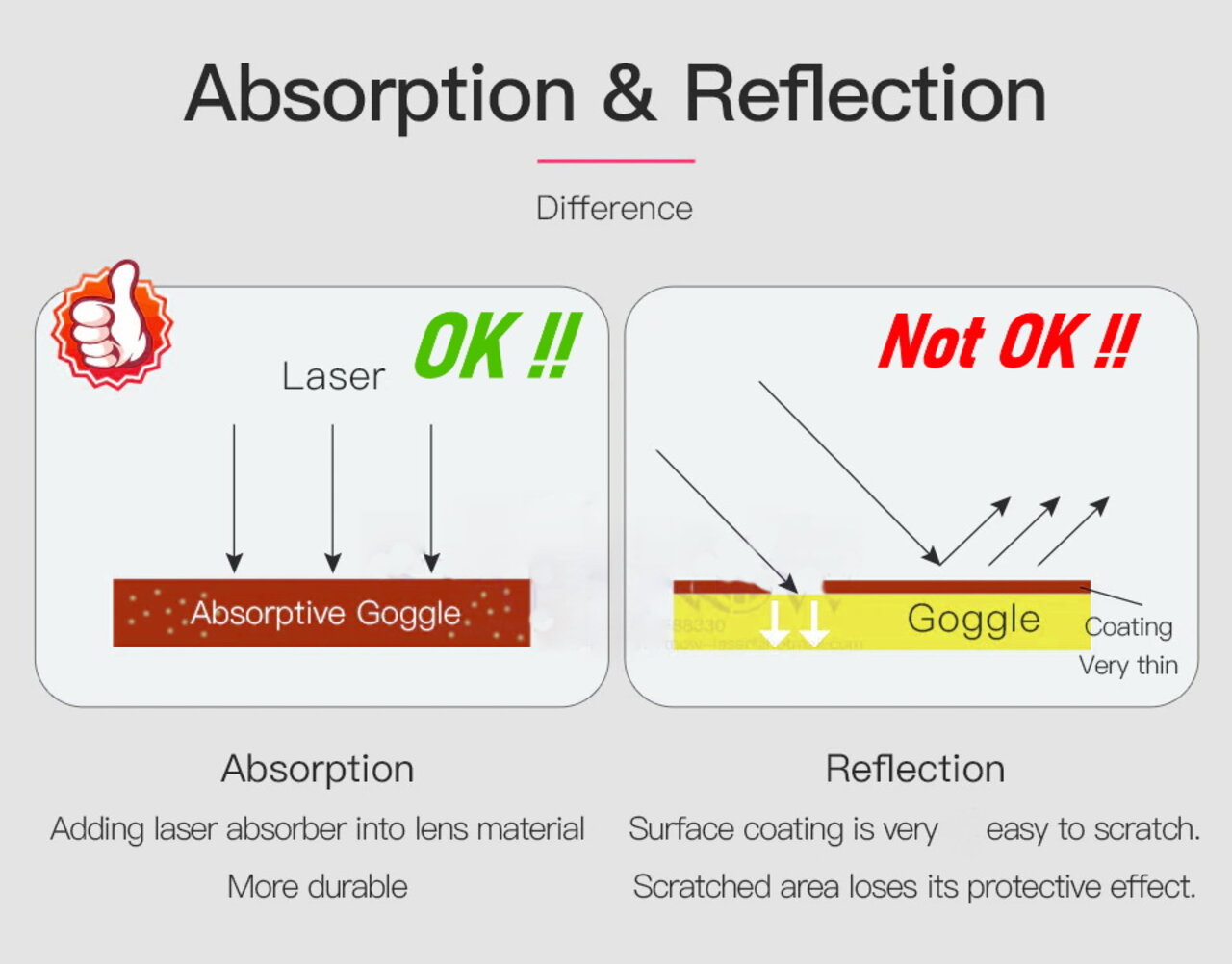

Coated protection goggles are not alowed as a small scratch in the coating makes them useless!! The lens material must contain the laser absobtion material thru all the lens-material.

Features of our Certified Laser Safety Glasses

These Laser Safety Glasses provide CE certified laser radiation protection. The lenses of all glasses are made from absorptive dye encapsulated in hardened polycarbonate, which provides superior resistance to breakage and prevents minor scratches from affecting laser protection.

- Laser Glasses Available in Multiple Frame Styles

- Absorptive Dye Encased in Hardened Polycarbonate Lenses (Resistant to Breaking)*

- Protection Lasts for a Minimum of 10 seconds at Maximum EN 207 Rated Exposure

- Certificates of Conformity Available for Compliance with:

- ANSI Z136.1 Standards for Safe Use of Lasers

- ANSI Z87.1-2003 Standards for Occupational and Educational Personal Eye and Face Protection Devices

- EN 207 Standards

- EN 208 Laser Alignment Standards

The optical density (OD) and LB-Rating for specific wavelength ranges are indelibly printed on the lens or frame for permanent identification without blocking the field of view.

Lasermach offers laser safety glasses in up to 12 different frame styles.

- The Universal style frames (model 8 & 11) can be worn over prescription glasses and features side and top shield protection from peripheral laser radiation.

- The Comfort style frame (model 1 ) features an extended adjusting.

- The Sport style frame (model 05) is designed to wrap around the user's face, providing full laser protection with a continuous field of view.

- Finally, the Modern Goggle style ( model 10 - ski goggle style) comes with built-in adjustable strap, making it the most secure of the frame styles.

Each pair of laser safety glasses comes with a protective storage case, cleaning cloth, and adjustable neck strap. However, the Model 10 Goggle style does not come with the separate neck strap as the neckstrap for the Model 10 Goggles is built in.

OUR SELECTED LASER WELDING SAFETY EYEWEAR For LASER WELDING

1064 ~ 1084 nm FIBER LASER SAFETY GLASSES - 1064 ~ 1084 nm YAG LASER SAFETY GOGGLES

Our selected eyeware for welding laser protection

Full range of excellent laser protective eyeware from Lasermach

Model 01 - Multi adjustable Frame Goggles

Excellent fitting Frame goggles for everyone

Model 05 - Ultra light adjustable protection Spectacle

Best in class for lightness and flexibility

Model 33 Perfect fitting for everyone without glasses: extra dark

Extra dark for sensible eyes

Model 304 - Frame Fit-over : Good fitting Protection Goggles for eveyone with glasses

Extra dark for sensible eyes

Model 08 - Frame Fit-over Good fitting Protection

Goggles for eveyone with and without prescription glasses!

MODEL 10 - O-FRAME 2.0 PRO Ventilated Ski Type Goggles with Laser Welding protective Lenses

SKI TYPE Goggles for the Active moving Welder

Whenn you want full protection in any position, this is the one you need!

Vertical, horizontal, above your head, this goggle stays on your head and gives you in any position a perfect protection

Laser Welding helmet full cover: comfort model

Face Shield full cover - High Comfort (new 2023 - 10)

The high-quality laser protective helmet fully protects the user's eyes and face during laser welding, and avoids direct or indirect impact damage to the human body caused by the laser.

Handheld Auto Darkening Laser Welding Helmets

Auto darkening Laser Welding protective face shields - Combi Laser safety and protection face shield mask for welding and laser welding. Full cover with metal protection - High comfort

Handheld Auto Darkening Laser Welding Helmets

Combi welding & Laser Welding protection auto darkening faceshields - Laser autodark Safety Face Shields : comfort model with metal shield protection cover

Protection Windows for safety cabins

The main application range is for our windows laser welding enclosures.

Laser Protection windows:

Maximum Dimensiosn : 1640 mm x 1000 mm

Safety windows for laser welding and laser cleaning

Protection Folie for Normal windows laser protection

Laser Protection Removable Film for Laser Welding and laser cleaning applications

Laser protection film for lasers in the IR laser welding and laser cleaning range

Download our special on Laser welding eyes protection

Get our Laser Welding Eyes protection special

Lasermach laser welding protection glasses - laser welding protection goggles - laser welding protection face shields - laser welding protection helmets - laser welding protection for eyes

GOTO our Download page to download the manual and price list

How to Clean and Care for Your Laser Safety Glasses

Clean, properly maintained laser safety equipment—whether glasses, face shields, windows or more—is essential to working safely with lasers.

Care Instructions for laser protection glasses

When not being used, the laser safety glasses should be stored in their protective case and in an area where the temperature does not exceed 30 °C. The cleaning cloth included with each pair of laser safety glasses can be used for removing dust from the surface of the lens. Products used for cleaning prescription eyeglasses are safe to use with our laser safety glasses. For disinfection of the glasses, we recommend mild detergent or soap and hot water or a dilution of isopropyl alcohol (up to 70% solution). We do not recommend any highly caustic solutions. The laser safety rating will not be affected by any of the above cleaning procedures.

Clean Laser Safety Glasses After Each Use

Cleaning your glasses after each use is an important part of protecting your investment. Remove any build-up or residue by hand-washing them with a gentle, household cleaner. Pat them gently dry with the included microfiber cloth. Ensure glasses are completely dry before placing them in their case.

- Do:

- Hand-wash only

- Use Windex or a gentle, household cleanser

- Store them in a hard-backed case

- Keep stored when not in use

- Do NOT:

- Wash with harsh or acidic cleansers or isopropyl alcohol

- Soak or immerse glasses

- Use abrasive cloth or paper-based textiles

- Autoclave or use disinfectant

Properly Store Laser Safety Glasses When Not in Use

All laser safety glasses purchased from Lasermach include a microfiber cloth and hard case. When not in use, the laser safety glasses should remain in the hard case. Loose glasses can easily become lost or damaged. Do not store anything other than glasses in the glasses case. Hard or abrasive objects within the case may scratch or damage the lenses.

Report Damages or Defects of your Laser Safety Glasses to Your Laser Safety Officer

Damage or disrepair to glasses can reduce their effectiveness and can expose the wearer’s eyes to dangerous levels of laser radiation. Replacing them can be costly and may delay or wholly prevent your ability to safely perform work with lasers. Proper cleaning and storage will help your glasses provide years of reliable laser protection.

Lens damage such as scratches, scrapes, or scuffs can impair the protection offered by your laser safety glasses. Visually inspect your glasses before each wear to ensure that the lenses are free from damage. Look to see that the frame fits securely around the lenses. Check the frame for anything that could cause the glasses to slip off during wear, such as cracks or warps to the temple/arms.

Do NOT use Damaged Laser Safety Glasses.

Make note of any damages you see and immediately report it to your Laser Safety Officer or supervisor. When in doubt, consult with your Laser Safety Officer or email us.

Picking the Appropriate Laser Safety Glasses

Since the correct choice of laser safety eye-wear depends upon many local factors that cannot be evaluated remotely, including the beam path, laser parameters, and lab or working environment, Lasermach can only recommend specific eye-wear for laser welding or laser cleaning with infra red-A lasers. We would recommend discussing your needs with your organization's laser safety officer.

PS: For maximum protection, our laser safety glasses should not be used more than five years from the production/buying date.

Absorbtion Protective goggles or reflecting protective goggles?

Which Protective goggles are the best?

Never use coated protection Glasses !!!

Every little scratch let full acces to your eye !!

Use only fully coloured lenses, with fully protection in the lenses itself.

Never use coated glasses as the slightest scratch in the coating makes your glases unsafe and not more usable!

Don't let your eyes destroy by cheaper coated safety glasses!!

Check how we are Testing our Laserwelding protection goggles !

Full power frontal shots from very nearby with high power laser shots - only good laser welding glasses resist this test!

Difference Between Optical Density and Absorbance

For absorbance measurements, the optical density (O.D.) is a logarithmic measurement of the percent transmission (%T) and it can be represented by the equation, A = log10 100 / %T.

The key difference between optical density and absorbance is that the optical density measurement takes both, the absorption and scattering of light, into consideration whereas absorbance measurement takes only the absorption of light into consideration. Optical density (OD) is the degree to which a refractive medium retards transmitted rays of light while absorbance is a measure of the capacity of a substance to absorb light of a specified wavelength.

That means a protection goggle with:

- 1 O.D. allows 10% of light to be transmitted through the sample = 10 times weaker

- 2 O.D. allows 1% of light to be transmitted through the sample = 100 times weaker

- 3 O.D. allows 0.1% of light to be transmitted through the sample = 1000 times weaker

- 4 O.D. allows 0.01% of light to be transmitted through the sample= 10.000 times weaker …

In other words, if a protection goggle has an O.D. (Optical Density) equal to 3, this means that only 1 photon of light out of 1,000 (10³) will be pass thru the protection goggle, if it has an O.D. equal to 7, this means that only 1 photon of light out of 10.000.000 will be pass thru the protection goggle. This means the light passing thru will be 1000 or 10.000.000 times less for the frequency indicated.

VISIBLE LIGHT TRANSMISSION (VLT)

When deciding which kind of lenses to purchase, a good place to start is with the visible light transmission (VLT). The higher the VLT percentage is, the lighter the lens tint will be. Higher VLT percentage lenses will allow for more light to travel through the lens that will then hit the eye. Alternatively, lenses with a lower VLT percentage will have a darker tint and will block more light from coming through to the eye.

Visibility Light Transmission (VLT) – Color and visibility of specific color ranges often are significantly affected by laser glasses and goggles. Think about sunglasses - when wearing sunglasses to block the sun, (often less expensive) sunglasses do an effective job of blocking the sun. However, everything is much more difficult to see because not a lot of light generally is coming through. Other times with (typically more expensive) sunglasses, the sun is blocked and everything else looks very similar to how it would without the glasses. We have selected the lenses with the highest VLT % with the highest protection possible for your Eyes and giving the nicest and clearest view of the objects.

Laser protection class 4 applies to our Wobble manual laser welding equipment when in operation.

Different measures are therefore required on the customer side to ensure laser safety, such as the appropriate training of employees, wearing special protective equipment and setting up a separate laser safety area.

PhotonWeld: High efficient portable handheld Laser Welding Machines

Visit our Webshop for all your laser Welding Protection equipment

https://shop.photonweld.com/

VISIT OUR WEBSHOP