PhotonWeld MASTER Pro Series: SIMPLY "THE" BEST!

Effective in the welding of thick steel sections - Outperforming our competitors

PhotonWeld MASTER-Pro Series: Designed for Heavy Industrial Fabrication

The Ecological Solution for the Heavy Welding Industry

Heavy industrial fabrication is defined by its focus on assembling thick metal sections, usually over 6mm in thickness, and constitutes a unique segment within the broader metalworking industry. In contrast to conventional welding processes, heavy fabrication requires a meticulous application of welding techniques tailored to meet the specific challenges posed by large metal components.

The complexity of heavy fabrication arises from the significant size and weight of the metal parts involved, necessitating specialized welding methods to create strong and reliable connections. Furthermore, heavy fabrication projects often operate under stringent regulatory requirements and industry standards to uphold the safety and integrity of the final product, underscoring the importance of precision and adherence to established protocols.

Unlike standard welding tasks that may involve thinner materials and simpler joint configurations, heavy fabrication demands a higher level of skill and precision from welders.

The only Laser Welding Machine with the sensational feeling and the looks of a standard Arc Welding Machine

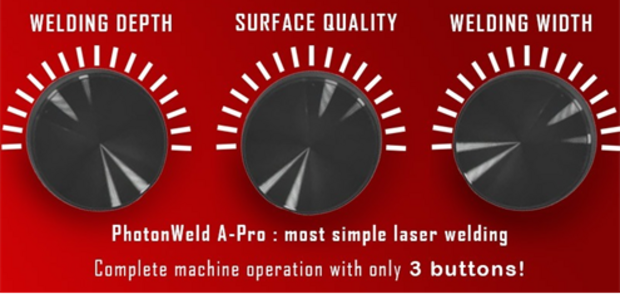

At PhotonWeld, we believe that advanced technology should simplify your work, not complicate it. No complex setup. No coding. No guesswork. That’s why we’ve developed the only laser welding controller that combines the power and precision of fiber laser welding with the intuitive feel of a traditional welding machine.

MAKE IT SIMPLE

Innovative Control Concepts witch gives you the feeling of using a standard Welding Machine

Innovative Control Concepts witch gives you the feeling of using a standard Welding Machine. The factory preset system automatically loads for you the optimal parameters for and ensures consistent high-quality laser welds.. Advanced operators can customize presets, and save for future use. It is obvious that this machine has been developed by the best welding specialists.

Most Easy controllable Laser welding machine on the market:

only 3 rotary dials for the 3 most important function: welding depth, Welding quality and welding width.

What does a welder needs more to work efficient and fast?

A Handheld Welder Engineered for Harsh Environments

Rain and metal dust-proof : respect the IPX3 and IP5X Standards

Common welding tools aren’t built for the real-world mess — dust, drops, dampness.

That’s where our IP54 Laser Handheld Welder with Rugged protection changes the game.

🔒 Sealed core components

🔌 Reinforced cable interfaces sideways mounted

💦 Certified to resist 60° liquid splashes (IPX3 waterproof & IP5X metal-dust proof)

📉 85% fewer dust-related failures

📉 75% fewer moisture-induced circuit problems

Less repair. Less unexpected downtime from dust or splash damage. More welding.

Groove Anti-Spatter Design: Proven 85% longer lens and protection window life.

Drastically reduction of downtime and hidden consumable expenses.

PhotoWeld’s patented dual anti-splash system reduces drastically the consumable costs but also leads to much less downtime.

We are Since 2022 the first on the market with our Anti-Splash Design:

- Engineered to deflect spatter away from the protective lens, reducing contamination by 80% and extending lens life by 5X+.

- Cost Savings: Fewer lens replacements mean up to 80% lower annual consumable costs.

- Enhanced Stability: Combined with advanced air-cooling, the torch maintains consistent performance even in high-intensity workflows.

While a single lens or protection window seems inexpensive, frequent burning of it triggers hidden high costs:

- Contaminated internal optics → skyrocketing repair bills;

- Unstable weld quality → higher rework rates;

- Downtime losses far exceed consumable expenses!

Fast adjustable and changeable Nozzle

Weld always with the perfect nozzle and the exact focus length

Our none rotating nozzle contruction and fixed focus tube increases the stability and the flexibility: better and faster changing nozzle.

- Adjust the focus length of your welding nozzle in seconds without rotation of the nozzle tube

- Change your nozzle, and only the top of the nozzle tube in a flash

- Never lose time with adjusting of totated nozzle

- Custom made nozzles are easy to make

- different nozzle-ends available for specific use

- changeover from nozzle in less than 20 seconds

- No blocking nozzles during mounting and dismounting