Assurer la qualité des soudures laser

Spécifications du processus et qualification des opérateurs pour le soudage par faisceau laser

Comme pour tous les procédés de soudage, le soudage laser doit être soigneusement contrôlé pour garantir la qualité. Un processus mal contrôlé ouvre la porte à des fissures, à une porosité, à une pénétration insuffisante et à un manque de fusion, qui pourraient entraîner une défaillance du joint de soudure s'ils sont présents en quantités suffisantes.

Vous vous dites peut-être : « Ces soudures sont si petites, comment diable suis-je censé garantir leur qualité ?! » La bonne nouvelle est qu’il existe des méthodes établies pour garantir la qualité des soudures laser. Voici les trois qui me paraissent les plus importants :

1. Une procédure de soudage écrite et qualifiée

Dans le monde du soudage, documentez les procédures de soudage à l’aide d’une spécification de procédure de soudage (WPS). Un WPS est un document qui spécifie toutes les variables essentielles qui doivent être définies et contrôlées lors de la réalisation d'un joint de soudure particulier. Certaines de ces variables essentielles sont la conception des joints, les types de métaux de base, les types de métaux d’apport, les gaz de protection, le type de laser et les paramètres du laser.

Un WPS doit généralement être qualifié (ou prouvé) par des tests. Cela implique généralement de réaliser des tests de soudure conformément au WPS et de soumettre les tests de soudure à des tests de matériaux appropriés pour garantir qu'ils répondent à toutes les exigences techniques. Les tests de qualification WPS peuvent inclure un contrôle non destructif (visuel, ressuage, rayons X, contrôle d'étanchéité) ou des tests destructifs (pliage, traction, dureté, métallographie). Les exigences exactes des tests sont généralement spécifiées dans les documents contractuels (dessins techniques ou spécifications de qualité). Les résultats des tests de qualification WPS sont documentés dans un dossier de qualification de procédure (PQR).

2. Opérateurs de soudage qualifiés

La personne qui utilise la machine à souder au laser doit être formée et doit démontrer sa capacité à réaliser des soudures répondant aux exigences de qualité applicables. La formation doit inclure non seulement le bon fonctionnement de l'équipement, mais également les considérations de sécurité liées au travail avec des lasers.

La démonstration des capacités de l'opérateur implique généralement des tests similaires à la qualification WPS. La qualification des opérateurs peut inclure des tests non destructifs et/ou destructifs, selon les exigences du contrat. Les résultats de ces tests sont documentés dans un dossier de test de qualification de processus de l'opérateur (OPQTR) ou sous une forme similaire.

3. Inspection de la qualité des pièces de production soudées

Pour garantir la qualité continue des pièces soudées au laser, un fabricant doit mettre en place une procédure d’assurance qualité. Les détails de cette procédure d'assurance qualité peuvent varier d'une organisation à l'autre ou d'un contrat à l'autre. La plupart comprendront des plans d'échantillonnage, des procédures d'inspection, des critères d'acceptation et une évaluation destructive périodique.

Le soudage au laser présente de nombreux avantages.

S'il est correctement contrôlé, il peut produire des joints de soudure fiables et de haute qualité dans votre produit.

This page is still under construction

ISO 15609-4:2009 - Specification and qualification of welding procedures for metallic materials

Welding procedure specification - Part 4: Laser beam welding

Abstract

ISO 15609-4:2009 specifies requirements for the content of the welding procedure specification (WPS) for laser beam welding processes, including overlay welding. It is not applicable to other processes for cladding (e.g. thermal spraying).

Variables listed in ISO 15609-4:2009 are those influencing the quality and properties of the welded joint.

This standard was last reviewed and confirmed in 2020. Therefore this version remains current.

Laser Welding Quality Related to Penetration

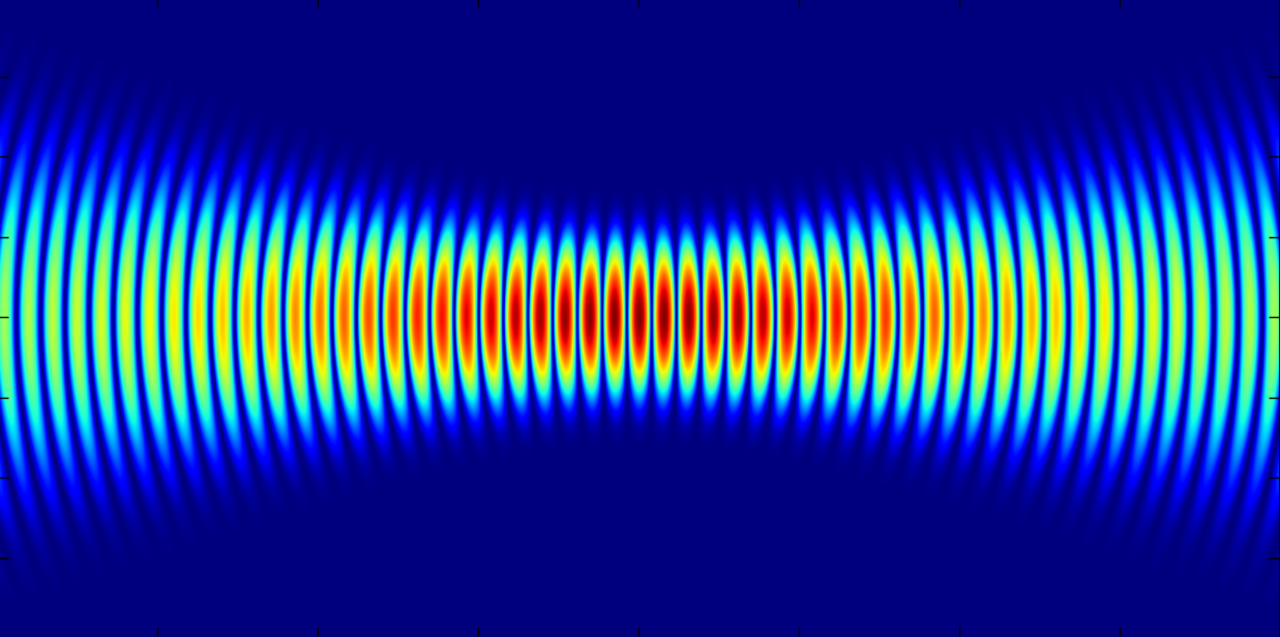

Penetration depth and penetration defects at laser Welding

The penetration depth is closely related to the joining strength. Any penetration defects on welds, such as inappropriate relationships between the penetration depth and base material, will greatly affect the quality and strength of welding. With butt laser welding as an example, the following describes typical penetration defects.

Insufficient penetration

A defect where the amount of penetration is insufficient compared to the required penetration depth due to factors such as insufficient application of heat to the molten metal. The figure shows an example of lap fillet welding. In butt welding, this defect easily occurs on the bottom of grooves. In the case of a thin plate tee (horizontal fillet) coupling, penetration is regarded as insufficient if the penetration depth is 20% or less of the thin plate.

Incomplete fusion

A defect in which parts of the base metal have not been penetrated by the molten metal. The figure shows an example of a thin plate tee (horizontal fillet) coupling. This defect is caused, for example, by the insufficient application of heat to the molten metal and pre-flow of molten metal. In circumferential welding, it is also caused by the preceding and succeeding beads being transferred to lap welding before they have penetrated sufficiently.

Photonweld laser welding quality inspection tools

Photonweld quality inspection tools

Photonweld laser welding inspection microscope

Portable Digital Laser Welding Microscope

Optical Size: 1/4″

Magnification: 50X-1000X

Focus Range: 10~40mm

Sensitivity: 4300mV/lux-sec

Resolution: 640*480, 1280*720, 1920*1080

Portable Digital laser Welding Microscope

A compact digital microscope for quality control of laser welded parts with versatile connectivity options such as WIFI and USB is available. This device can seamlessly link to phones, tablets, laptops, and PCs, displaying images directly without the need for direct observation. Using the accompanying app, capturing photos and videos is straightforward, and the images can be easily saved.

The Portable Digital Microscope boasts comprehensive functionality, delivering clear imaging with meticulous craftsmanship. It features a built-in battery, facilitates computer connections and is compact and portable.

This portable digital microscope finds besides laser welding quality inspection, extensive applications across various fields, including electronic circuit board testing, industrial assessments, textile examinations, clock and mobile phone maintenance, skin and scalp inspections, printing assessments, educational and research purposes, precision object amplification measurement, aiding in reading and serving as a valuable tool for hobbyist research.

The welding procedure and its quality is dependent on ensuring that every step is done correctly. It is a technical task that requires proper certification, safety regulations, and training. Any damage to the welding part can be costly and might cause permanent structural damages to the final product.

Welding is a part of many industries such as construction, aviation, automotive, and more, and each of them demands quality assurance. Ensuring everything is welded perfectly together beforehand will protect you from hazardous incidents that can often take lives. Therefore, if you are thinking about hiring a welding service, make sure to receive the service from a reliable welding specialist who knows how to do this job.

Full penetration laser welding, partial penetration laser welding, and their strength

Different grooves also cause different patterns of penetration, leading to differences in the strength of welds.

Full penetration laser welding

Full penetration welding is a welding method in which the groove of the base material to be joined is united and embedded with molten joining materials (filler rod and welding wire), as with butt welding.

It can be said that full penetration welds are highly reliable in strength design as they have the same proof stress as the base material. On the other hand, they require high welding quality. Particular attention is required at the ends of welds to prevent defects such as undercut welds. It is also important to control and adjust reinforcement because stress concentrates on excessive reinforcement, causing cracking or other such problems.

Partial penetration laser welding

Partial penetration welding is a method in which a partial groove is created on the base material. In this method, the base material is only welded partially, while full penetration welding welds the entire plate thickness of the base material. Although full penetration welding is used in general, partial penetration welding is required in some cases, such as where joined sections are intertwined due to the design and manufacturing of materials.

However, caution is required during partial penetration welding on locations to which bending moment or tensile force is applied because the welding strength of partial penetration welding is often not sufficient. Thus, the strength design of welds, as well as the measurement and inspection of whether dimensions of actual weld penetration such as throat thickness satisfy the design conditions, are all particularly important.