Laser Welding in the Automotive Industry

You have to have precise accuracy during the manufacturing process within the automotive sector. In order to obtain a high-quality outcome that is both time and cost-efficient, you must be precise. Within this market sector, it is vital that all parts are safe and secure which, with the intricacy of laser welding, you can guarantee. Consequently, the applications of laser welding are actually most prominent in the manufacture and repair of automotive parts. However, time and cost efficiency are not the only benefits to utilising laser welding in the automotive industry.

Laser Welding of Components of Automotive suppliers

Reducing costs and boosting quality are particularly important as part of the production of components within the automotive supplier industry. For instance, as part of axle, shock absorber, gear parts and powertrain parts, exhaust system, seat, and wheel production as well as many other components. In these areas, wobble laser welding anti-spatter behavior and low HAZ zone, can make a significant contribution to protection from enormous rework costs.

Wobble Laser Welding of components saves reworking costs and maintains the quality of metal surfaces.

Wobble laser welding prevent metal spatter on components — at linking points, threads, in visible areas — and in general help to obtain ideal corrosion protection.

Wobble laser Welding saves cleaning costs, boosts service life, and prevents faults.

For instance, in axle production, it is widely used in MAG welding processes to use chemical covering layers., in gear part production it is used to put protection layers for protection of jigs. The use of wobble laser Welding increases the service life and the (dry ice) cleaning intervals, — simply put, it saves cost

Laser Welding in Automotive Industry

Dynamic Processes like laser welding Open Up New Possibilities

Today, there is no modern vehicle on the streets, in which laser was not applied. Whether laser welded tailored blanks, gear components or car keys – the applications are multiple.

Dynamic Beam Welding

Within the shortest possible time multi spot welds of any geometry can be generated with Dynamic Beam Welding Systems in a very large work space. This system technology is applied amongst others in the production of automobile seats and mountings.

Laser Welding of Battery Housings

Helium-tight seam welding with laser and galvanometric scanner. For this application high reflective materials such as copper or aluminum are welded with a fiber laser. Besides many other industries, the batteries are used for example within the automotive industry

Laser Welding for the Connection of Battery Cells

Single battery cells are connected in series or parallel within a battery module. This is realized by the electrical connection of the contact tabs/arrestors. During the welding process for contacting, the heat input must be kept at a minimum, making the laser the ideal tool. Because high reflecting materials such as copper or aluminum have to be joined, the fiber laser in combination with a wobble solution is the right choice for this application. Usually for this application output powers of up to 2 kW are used. Together with further peripheral components, several battery modules are assembled to one battery pack for use e.g. in electric cars.

Spot Welding of Copper Conductors for Electric Motors

For this application a high number of welds per part have to be realized. With scanner and fiber laser, the laser beam can be positioned from weld to weld within milliseconds. Adjusted scanner movements melt the copper so that broad welding gaps can be bridged. Due to their high absorption into highly reflective materials such as copper, the fiber laser is the right tool for this application. Another advantage of laser welding with the fiber laser is the low heat input due to very short process times. Therefore damaging the isolations because of high temperatures can be avoided.

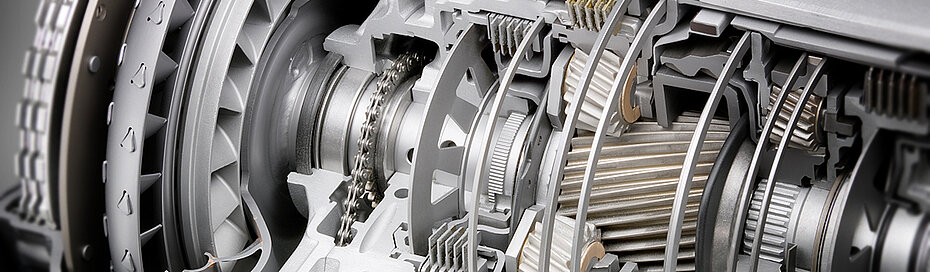

Laser Welding of Gears and Powertrain Components

Using lasers, gear components made from high-strength steels can be welded without cracking. The welding of gear components using laser could be established already a long time ago due to its advantages such as low maintenance costs, low distortions at the work piece, high flexibility and simple automation.

Laser Welding of Tailored Blanks

Tailored blanks consist of laser joined flat sheets of different material thicknesses and alloys. Linear as well as non-linear joints are generated. Due to the strength and ductility of the laser-welded seams, the tailored blanks can be subsequently stamped into components such as car doors.

As part of the preparation of high strength tailored blanks out of manganese-boron steel prior to laser-welding, q-switched solid-state lasers can be used for decoating the aluminum-silica layer.

Laser Welding of Air Conditioning Cooling Pipes

For welding the aluminum of this air conditioning part, our fiber lasers are the ideal choice. The shorter 1um wavelength is much better absorbed by high reflective materials such as copper, aluminum or brass, compared to longer wavelengths.

Laser Welding of Brake Sensors

The steel of ABS brake sensors is welded with high-power fiber lasers. Besides the brake sensors also various other sensors like pressure sensors, force sensors and air-bag sensors are welded by laser.

Laser Welding of Exhaust System Components

Stainless steel heat exchanger tubes are welded with laser scanner solutions in combination with our high power fiber lasers. Stainless steel exhaust couplings and sleeves can be either welded with fiber or CO2lasers

Laser Welding of SCR Injectors

To meet the emission standards, the harmful nitrogen oxides are converted into the air components nitrogen, water and carbon dioxide by selective catalytic reduction (SCR method). The selective Catalytic Reduction (SCR) Injectors are welded with Wobble driven fiber lasers and are used for AdBlue injection in large diesel engines.