Laser additive manufacturing machines with wire feed (WLAN)

The ability to build a 3D volume through the supply of molten wire by laser beam is called Laser-Wire Additive Manufacturing (WLAM), Less expensive than powder, the use of wire as filler metal guarantees almost 100% material yield and eliminates the constraints associated with powder management. The laser beam allows better control of heat input compared to arc-wire additive manufacturing processes. This feature makes it possible to limit thermal deformations during deposition cycles while improving the properties of the post-process part. has improved, This process becomes close to laser brazing.

Advantages of laser additive manufacturing machines with wire feed:

- Reduced raw material cost

- Material yield equal to 100%

- Removal of constraints related to the filler metal in powder form

- Versatile machine that can be used for reloading, part repair or additive manufacturing

- Better heat control

Powder spray laser additive manufacturing (LMD) machines

In order to be able to work on larger volumes, laser additive construction machines by powder spraying began to emerge. Based on the same technology as that used for the repair of aeronautical parts, the powder is projected and melted by a laser beam leaving a high pressure nozzle (reloading head). This process makes it possible to produce parts of greater volume but require draconian protection due to the environment in which the powder is projected: inlet airlock, overpressure room, suit for operators with air filtration, recycling of powders, etc.

Advantages of powder spray laser additive manufacturing machines:

- Low thermal input

- Repair and reloading of parts

- Deposits of different composition on the substrate

Powder bed laser additive manufacturing (SLM) machines

The democratization of consumer 3D printing has changed the function of deposited parts and the way we design them. SLM-type laser additive manufacturing makes it possible to produce ceramic, metallic or polymer parts from the fusion of successive layers of powder.

Used for making small parts, SLM machines allow high dimensional accuracy to be achieved on parts of high geometric complexity.

Advantage of powder bed laser additive manufacturing (SLM) machines:

- High geometric complexity

- High dimensional accuracy

- Good surface condition

- Post-machining not necessary

Laser additive manufacturing machines with wire feed

Thanks to recent advances in optical laser devices, the ability to build a 3D volume through the supply of molten wire by laser beam has improved, thus arousing the interest of manufacturers. This process, close to laser brazing, is called laser-wire additive manufacturing (or WLAM for Wire Laser Additive Manufacturing).

Less expensive than powder, the use of wire as filler metal guarantees 100% material yield and eliminates the constraints associated with powder management. The laser beam allows better control of heat input compared to arc-wire additive manufacturing processes. This feature makes it possible to limit thermal deformations during deposition cycles while improving the properties of the post-process part.

Currently, laser-wire additive manufacturing offers an alternative to arc processes for the production of large parts with a minimum of thermal deformation.

Current research still needs to deepen knowledge of the process in order to diversify the materials that can be deposited. The first parts produced allow a wide variety of applications to be envisaged, such as reloading/cladding, repair or the creation of a 3D volume. Several research programs have been launched in France and in Europe in order to better master and expand the applications of this new laser-wire additive manufacturing process.

Industrial Laser Systems is also participating in one of these programs with the objective of developing an industrial demonstrator that will serve as the basis for a standard laser-wire additive manufacturing machine.

Advantages of laser additive manufacturing machines with wire feed:

- Reduced raw material cost

- Material yield equal to 100%

- Removal of constraints related to the filler metal in powder form

- Versatile machine that can be used for reloading, part repair or additive manufacturing

- Better heat control

- Reduced manufacturing time

- Limited environmental impact

- Less machining

- Supply chain savings

- Less parts flow

- Excellent metallurgical quality

- Production of single parts and small runs

- Large parts possible

- High construction speeds

- Multi-material manufacturing

- Manufacturing of obsolete parts

- Distortion control

- Use of the right amount of material

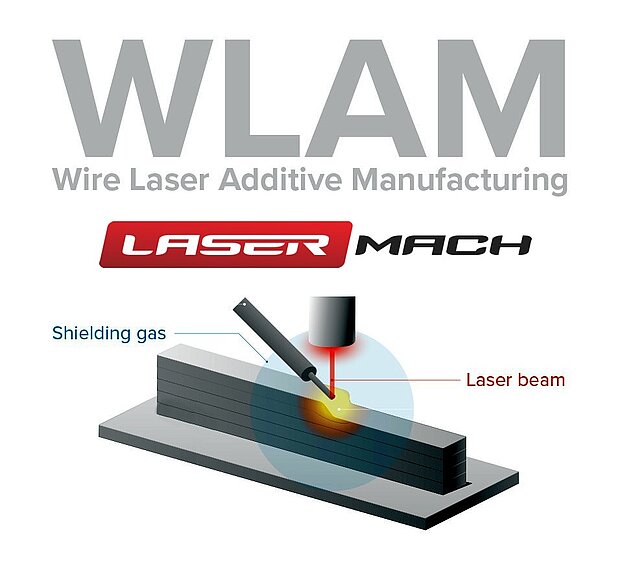

WLAM (Wire Laser Additive Manufacturing)

The WLAM (DED - Direct Energy Deposition) process allows for the creation of 3D parts using a laser beam to add molten wire.

This WLAM technique produces very good internal quality (no porosity) and improves deposition precision, with a much more stable and consistent bead (0,8~2,2 mm) compared to Arc processes (3 to 8 mm).

Excellent metallurgical quality

Large parts (up to 12 m)

High build speeds depending on the material

Very Low energy consumption compared to normal WAAM (till minus 85% less)

Multi-material manufacturing

Controlled deformation

Use of the “right material”

Diversity of materials due to the availability of welding wire

High metallurgical quality

Wire laser additive manufacturing

Wire Laser Additive Manufacturing (WLAM) is a form of additive manufacturing where a wire feedstock is used as the material source, and a laser provides the heat source for melting the wire to form a part layer by layer.

A laser heats and melts a metal wire, which is fed into the melt pool.

The wire can be fed coaxially with the laser beam or at an angle, and the movement of the laser head or the workpiece platform builds the part layer by layer.

Additive manufacturing with Laser and wire feeder: WLAM

Additive Manufactoring with Wire

Additive manufacturing is a comparably new production method, involving a component being constructed via layer-by-layer material coating. Originally developed for prototyping, today it is mainly used for the production of geometrically complex components in small batch sizes from 1 to 1,000. Here, additive manufacturing is more economical than conventional methods, for the most part.

Advantages of WLAM

Efficiency:

WLAM can have high material efficiency, often exceeding 90%, as there is minimal waste compared to powder-based methods.

Cost-Effectiveness:

Generally, wire is cheaper than metal powders used in other AM processes, and there's no need for expensive powder handling systems.

Large Parts:

Suitable for manufacturing large parts due to the high deposition rates compared to powder bed fusion.

Material Variety:

A wide range of materials can be used, including titanium alloys, stainless steels, aluminum, nickel alloys, etc., as long as they are available in wire form.

Safety:

Less environmental contamination risk since wire doesn't aerosolize like powders can.

Low energy consumption:

Compare to normal welding our technology can consume till 85% LESS energy

Additive manufacturing applications – overview

How does additive manufacturing work?

The main tool involved in metal additive manufacturing is a system which contains a laser, a movable metal deposition head and a metal powder nozzle or wire feeder. The metal deposition head or the wire feeder head, which are suitable for 3D printing, is moved over a building platform while it adds the metal powder or the wire by heating it with the laser beam and melting it on the surface. After the material has been cooled down, the next metal layer can be applied, thereby additively generating a three-dimensional component in accordance with the construction plan. The technical principle of the additive manufacturing process is basically the same as the cladding process. The difference is that it does not revolve around two-dimensional layers: instead, three-dimensional forms are created.

Laser brazing machines with wire feed

Laser brazing is a process of assembling identical or dissimilar materials by means of a supply of material.

Laser brazing with wire feed allows the assembly of sheets by means of a wire feed that is melted in contact with the beam and the parts to be assembled. Laser brazing allows the assembly of parts thanks to a supply of wire. This is melted by the laser beam and allows, once solidified, the connection of the two parts to be assembled. Laser brazing is mainly used for so-called "mixed" assembly on sheets of different compositions.

Laser brazing can also be carried out with the addition of an intermediate interface (foil, paste, etc.) placed between the two parts to be assembled.

In the case of brazing by adding an intermediate interface (foil, paste, etc.), the optics used will integrate a homogenizer element in order to uniformly heat the area to be assembled.

Therefore, the choice of filler metal will depend on the materials to be assembled to obtain the best mechanical properties. Laser brazing allows better control of heat input in thinner sheet type of application. A laser brazing head is used to shape the laser beam thereby achieving the desired characteristics of the beam at the focal point. Ideal for welds along a curve, laser brazing achieves speeds of several meters per minute with a smooth finish and high mechanical strength of the weld bead.