Affordable Automation

All the benefits of advanced robotic automation without the extra costs and hassle. Cobots are portable. Easy to set up and program. No shielded work cells needed. Practical Job Shop Automation!

Expand Your People Power

Our cobots let you expand your people power so one operator can run three or four machines at once instead of two. Let the cobots do the monotonous work to let your machinists utilize their skills and knowledge to optimize your manufacturing operations.

Maximize Your Profits

Reduce production downtime and increase quality with precision and high repeatability every time with cobots. Cobots can work 24 hours a day and seven days a week.

Connect to the all the Different cobot brands

Collaborative robots are becoming increasingly important and the demand for automation is growing. It is therefore not surprising that the number of types of cobots has increased significantly in recent years. In total, there are now about 65 different cobot manufacturers that focus on the production and development of cobots.

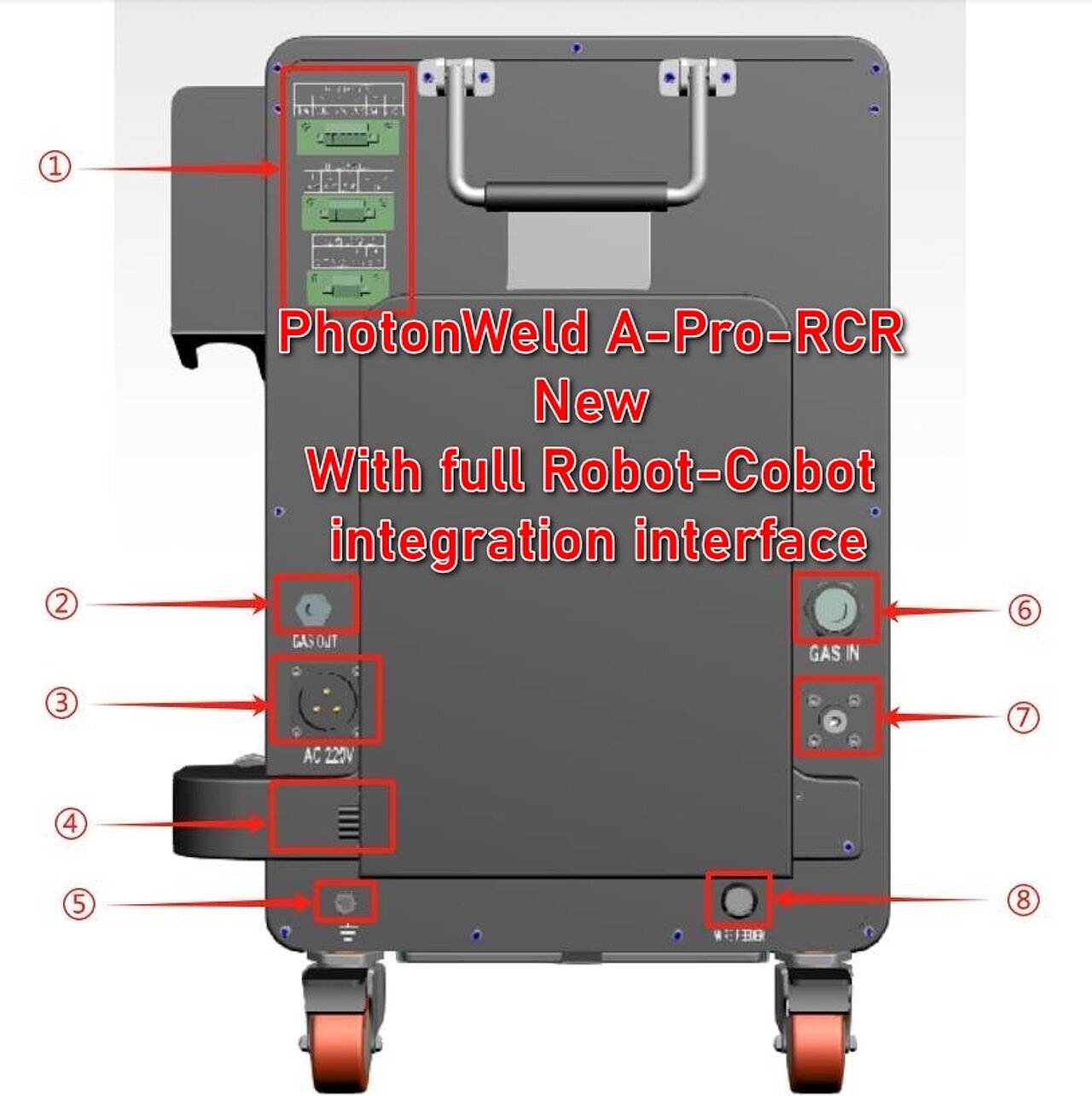

Our PhotonWeld C-Series connects to all Robots, cobots and automated systems with 6 I/O's only

ABB Robotics

Aubo Cobotics

Doosan Robotics

Fanuc Robotics

Franka Emika robotics

Jaka Robotics

Kuka Robotics

Mitsubischi Electronics robotics

Omron Robotics

Stäubli Robotics

Siasun Robots

Techman Robot

Universal Robots

Yaskawa robotics

Kawasaki Robotics

OTC Daihen

Cloos Robotics

Hyundai Robotics

CONNECT WITH MOST COBOTS

BOOST YOUR LASER WELDING PERFORMANCE WITH COBOTICS

With the Direct Connect module, PhotonWeld's cobot-ready welding machine can easily be connected to many different cobot brands. Connecting the existing manual welding machine with a cobot saves time and money and offers a kick-start to automated welding.

Collaborative robots, cobots, have come to the markets with force since they offer lightweight design, flexibility, and intelligence with a reasonable investment. Workers can quickly teach cobots specific welding applications and have them working on actual welding while operators can concentrate on different activities.

Lasermach offers an easy and fast-to-set-up cobot welding solution consisting of a laser welding machine (incl. power source, wire feeder, welding torch) as a base, a compact direct Digital Connection Module (DCM) Cobot interface, A-Pro torch holder, and a mobile app. The flexible DCM module connects the PhotonWeld A-Pro laser welding machine with the cobot (any cobot). For the laser welding machine, Lasermach has a wide range of cobot/robot -ready alternatives. The torch holder is designed so that the manual welding torch can be fitted to it. It has a quick attachment system so the welder can effortlessly detach the torch from the cobot and add manual welding to the workflow.