The new PhotonWeld A-Pro T45 handheld laser welding machine inherits the excellent quality of the A-Pro series product family and continues to demonstrate its strong adaptability and stability.

Whether it is in the severe cold of -30°C, the scorching heat of 60°C , or in a high humidity environment of 90% , it can achieve 7*24 hours of uninterrupted continuous light output .

PhotonWeld A-Pro T45

Lightweight

Weight 36kg

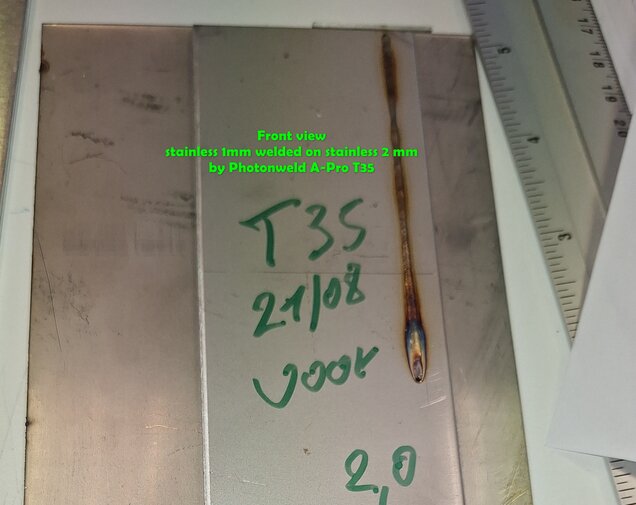

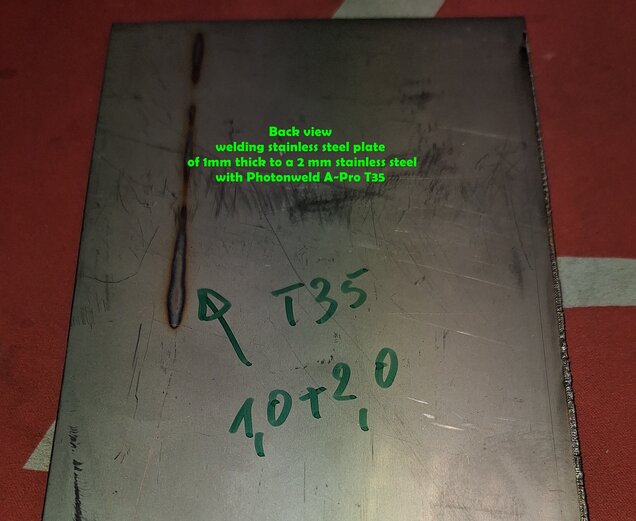

Welding Thickness

0,2 ~ 3,5 mm

Uptime

7 x 24/24h

Working Temperature

-20°C ~ -60°C

Noise Level

< 50dB

More efficient, better and more affordable

Providing customers with "more efficient, better and more affordable" laser products has always been the first priority of the R&D team of Lasermach, and at the beginning of 2024, we launch the new designed "Desktop" handheld laser welding machine model PhotonWeld A-Pro T45, which is targeted at solving the problems of the users such as inability to weld continuously, high noise, bulky and inconvenient to move the equipment, and to create a more suitable for the users of the handheld welding series products. This new product not only has excellent environmental adaptability, but also has been fully upgraded in details.

Ultra-Portable -+- Ultra-Quiet -+- Non-Stop Welding at 100% from -20°c ~+60°C

Temperature control upgrade

PhotonWeld A-Pro T35 has been upgraded based on the original heat dissipation structure of the much bigger and more power-full T70, to make the heat dissipation surface wider and ensuring further the stability of the internal temperature of the machine during welding work, keeping it within the optimal working temperature range, thereby ensuring the reliability and the continuity of the welding quality .

According to test data, under 100% full power laser light emission at +60°C environmental temperature, our new PhotonWeld A-Pro T35 still maintains the optimal internal operating temperature of around 30°C, with a maximum fluctuation of +1.1°C.

Structural upgrade

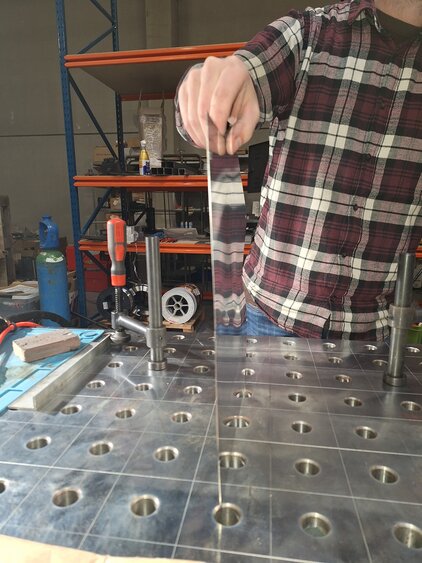

The New PhotonWeld A-Pro T35 handheld welding machine has undergone a new optimization and reorganization in the structural design, achieving significant weight reduction. The new design with compressor driven heatpump weights only 36KG . The lightweight design makes outdoor welding work easier and more comfortable, even for women. The operator can also move easily, which greatly reduces the physical burden of long-term work.

Noise reduction upgrade

Low Decibel, Ultra quiet

In response to the noise pollution problems reported by customers from automated assembly line welding, we have mastered the noise to a level below 50dB , providing operators with a quieter and more comfortable working environment.

Our new T35 Handheld Laser Welder is uniquely designed with special emphasis on minimizing noise during operation, providing a more comfortable working environment for users. Compared to other welding equipment, the PhotonWeld A-Pro T35 handheld laser welder not only improves work efficiency, but also greatly improves the user's work experience and reduces hearing fatigue that can occur during long hours of work. Whether it's a work area with strict noise level requirements or a dense workplace, Lasermach's handheld laser welder can meet the most stringent demands.

Performance upgrade

Non-Stop Welding under 100% load and 100% duty

Unlike traditional air-cooled handheld welding that involves downtime processing, Lasermach's forced air-cooled handheld welding machine based on the efficiency of a compressor driven heatpump, allows continuous welding without any downtime. Continuous operation is realized in the ambient temperature of -20~+60℃.

As result you can keep your processing efficiency double high compared to the others because you are not limited by downtime, not limited by process, not limited by place, not limited by the season and certainly not limited by environmental higher temperature.

Safety Upgrade

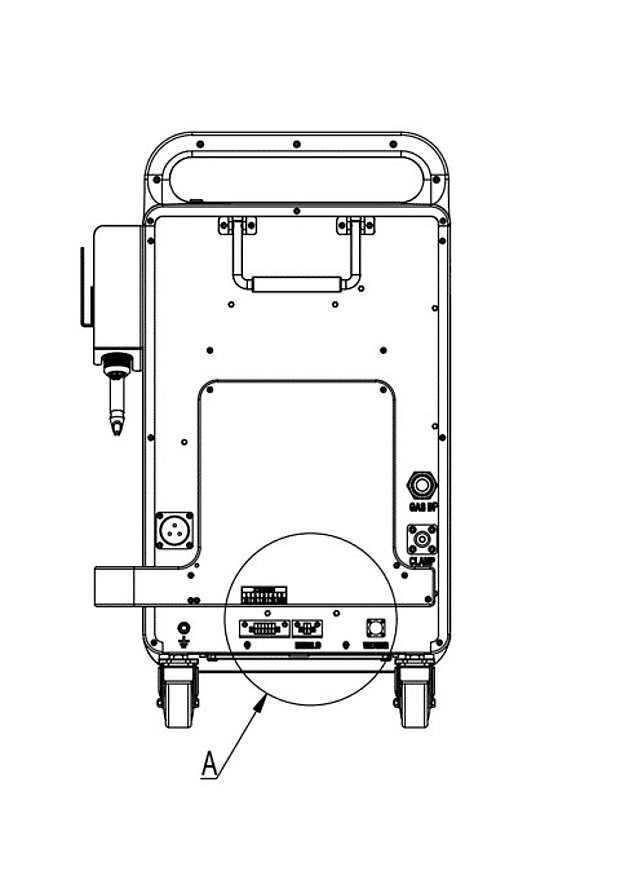

Lasermach aims to provide a safer experience for welding workers from the customer's point of view. PhotonWeld's new generation of handheld laser welder integrates multiple safety protection functions, including input gas pressure detection, torch head light out security circuit, laser enable CNC switch, LOOP safety lock, double wired emergency stop button, laser power switch, direct door safety contact connection, and so on.

Meanwhile, it has five major alarm monitoring (temperature alarm, current alarm, voltage alarm, gas pressure alarm, open torch alarm), which provides users with all-around, intelligent safety protection and makes welding operation more controllable, intelligent and peace of mind.

More upgrades

In order to ensure that the new PhotonWeld A-Pro T35 handheld laser welding machine can operate stable in various harsh environments, we have also upgraded it in many aspects such as dust-proof (IP4X level), waterproof (IPX3 level), shockproof, and drop-proof, High low temperature resistance , and have strictly tested and checked it at every level.

These tests not only guarantee the quality of our new PhotonWeld A-Pro T35 handheld laser welding machine, but also fullfill our commitment to customers. We firmly believe that only through such strict screening and testing can we ensure that every new product shipped from the factory can provide customers with a stable and reliable welding experience. We are also confident that this product will continue the good reputation of the PhotonWeld A-Pro series products in the market and win the favour and trust of more customers.

PhotonWeld A-Pro T-Series

Available with Optional COBOT ROBOT interface

Start your automation with your own existing Robot.

Connect our Photonweld A-Pro T-Series to any Robot and Cobot.

Very simple and easy interface.

No need for high level programming!

Need only 5 contacts from your robot or cobot.

PhotonWeld A-PRO T45 for Automotive Bodywork - CAR BODY REPAIR

Car bodywork welding - Auto Body Welding Solutions - Collision Repair welding - Which laser welder for automotive body restoration?

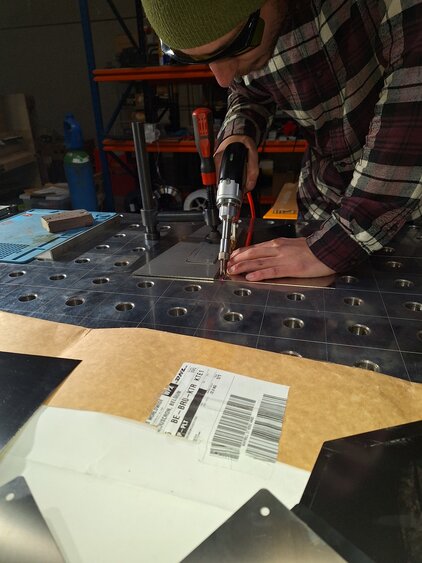

Whether you’re a hobbyist or seriously into auto-body work, having a good welder makes all the difference in finishing your cars quickly and to the highest quality.

There are plenty of welders to choose from, and everyone has their own opinion of what they like, so not every welder we have below will suit you. However, we have developped the VERY BEST welder for automotive work:

- VERY FAST : 5~7 times faster than TIG or MIG

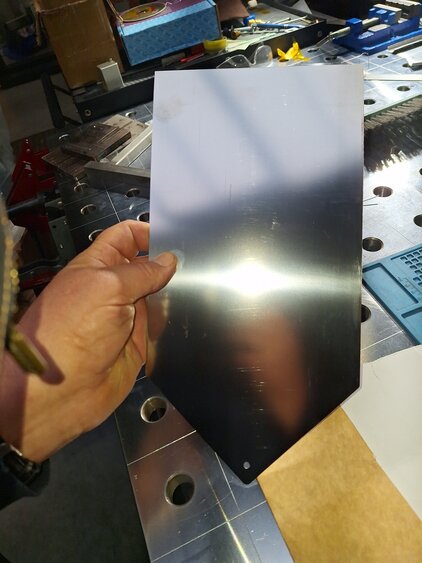

- Without deformation: due to the very low and local heat input you do not get any deformation of the thin sheets

- No need for heavy Protection

- Very economical : reduce the electrical consumption with almost 70%

- Easy to use - simple to learn

- The only Ecological responsable Welding Machine

Whether you’re a MIG welder, a TIG welder, or want a machine you can do both with, werecommend you to check our affordable PhotonWeld-A800-bodywork.

Laser Welding Applications In The Car Restoration Industry - Laser Welding Applications In The Car Refurbishment Industry

Laser welding in car repair and automotive repair

During car restoration, if any of the panels of the car needs to be replaced, the welding quality and perfect weld bead must be ensured. However, traditional argon arc welding has a relatively large thermal impact on automobile repair and refurbishment, which can easily cause thin plates to easily deform a lot. At the same time, the welding spots formed by argon arc welding are relatively much to large, and they need to be polished intensively after welding, this to meet the requirements. .

Therefore, in the automobile repair and refurbishment industry, laser welding machines have great advantages over traditional argon arc welding. Handheld laser welding is becoming more and more widely used. in the car repair industry.

Welding techniques in bodywork repair

Vehicles can only be repaired correctly if the right choice is made from the variety of new joining techniques for the modern materials and low sheet thicknesses which have been used in recent times to manufacture new vehicles.

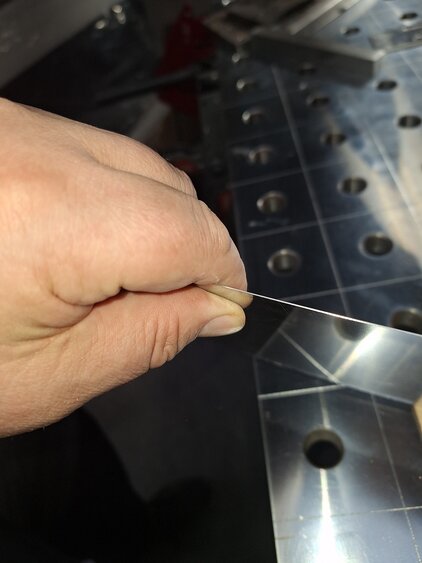

Looking at the two main areas of bodywork repair, structural parts and outer skin, the welding machine being used needs to offer both MIG/MAG welding processes and MIG brazing, and must be capable of joining panels with a thickness range of 0.4mm to 4.0 mm. This dictates the use of a welding machine which fully meets these tasks for all areas, without time-consuming setup procedures. This you can find in our PhotonWeld-A-PRO-T40 portable Laser Welding Machine.

Any car enthusiast from home to the professional restoration company, whether historic or modern race preparation will have a use for this low heat input welding process.

Handheld Laser Welding is today applied in modern and historic car parts, ranging from Formula 1 to your rare historic vehicles working along side some of the top historic restoration firms in the country.

The benefits of using Laser Welding over other more conventional means such as Tig, Mig and Electron Beam are as follows:-

- No pre-heating of the part is required

- Heat distortion is virtually zero, large areas can be built up without any concern of the part moving, the ability to weld without distortion saves time, and money spent on attempting to recover the part that has distorted therefore no extra machining cost or even the chance of having to scrap the part are involved.

- Very old and corroded parts can be welded, many historic parts that would normally be beyond normal Tig welding due to the porosity and corrosion can be brought back to life with laser welding.

- The heat effected zone is very small which means the part being welded would not rise above 30°C and the structure of the base material remains the same. This allows any hardening treatment done to the part prior to welding will remain the same.

- Areas can be accessed that need welding which would be impossible with Tig.

- Parts can be welded either before or after hardening with the hardness value of the material being matched or coated with a harder wearing coating.

- A wide range of materials can be welded both ferrous and non ferrous such as

- Aluminium

- Brass

- Bronzes

- Carbon Steels

- Cast Iron

- Copper

- Inconnel

- Magnesium

- Stainless Steels

- Cortensteel

- Titanium,…