Weld Package dual Wire 2.0 For high welding speed and high deposition rate

In short, the dual wire feed of laser welding machine is widely used in various fields. It can improve welding efficiency, welding quality and product performance. It is a very promising welding technology.

Process Benefits of dual wire laser welding

High travel speed and High deposit rate are the biggest beneifits of dual wire laser welding

Process Benefits of Dual wire feeding

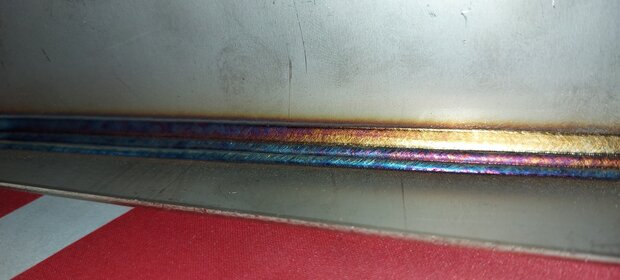

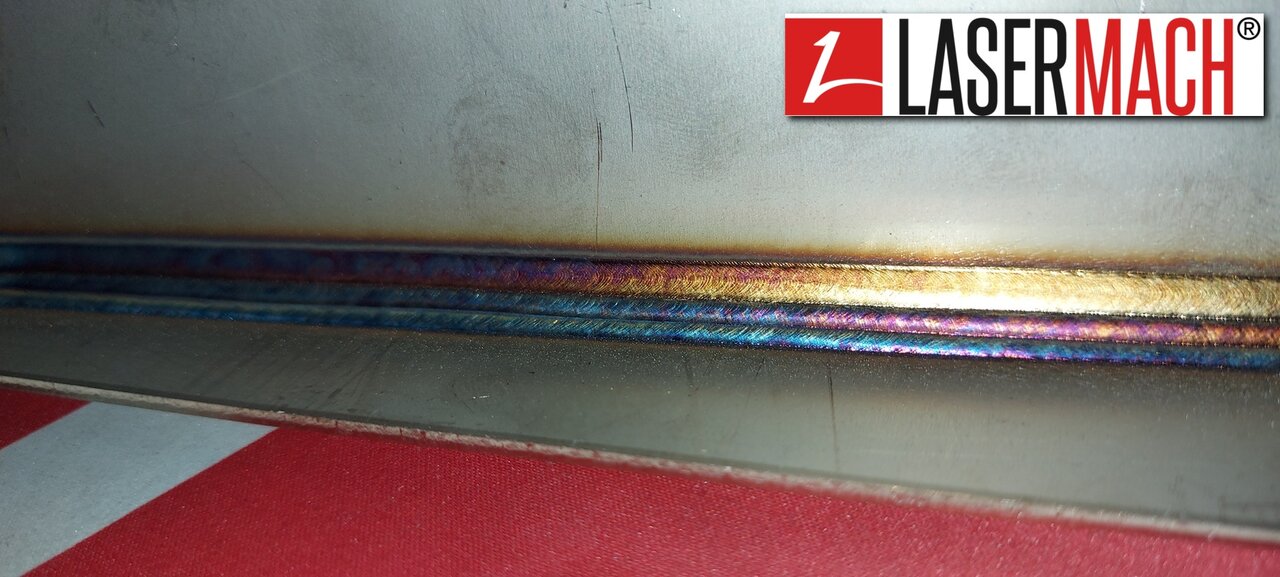

The Dual Wire Laser Welding process has a wide operating range that can be generally segmented into two catagrories addressing high speed sheet metal welding and heavy plate welding. On sheet metal, the process is often operated at travel speeds in excess of 250 cm/min on thin gauge material. On heavy gage material, weld metal deposition rates exceed drastically the standard laserweldin results.

High travel speed applications

The ability to distribute the total welding enrgy across two separate welding wires provides unique benefits for high-speed welding. When pushed to increase travel speeds on thin gauge metal components in industries such as automotive, tank and general sheet metal fabrication, welding operations are faced with one or two quality issues, either burn through or lack of weld metal follow characteristics.

The double Wire process addresses both of these speed-limiting issues. The ability to distribute the necessary welding energy over two welding wires allows to generate needed penetration while on the back edge of the weld puddle creating added fill. This double wire behavior in the shared weld puddle provides excellent gap filling characteristics. Improved gap filling capabilities are of particular value to industries processing high volumes of stamped or formed parts.

High deposit rate applications

The Dual wire feeding process can on average represent a 30-80% increase in deposition potential when compared to conventional single-wire processes. The Dual wire process typically employs medium diameter wire. As higher welding energy is applied to the small diameter electrodes (1,2 - 1,6mm) the wire melt-off rate rises exponentially. The resulting wire melt-off rate for a given energy draw is a little lower for dual wire welding than that of a single large diameter electrode. This higher melt-off rate potential and lower energy draw provides unique benefits for the heavy plate fabricating industry. The high deposit rate obviously provides the means for improved production throughput. The lower heat input can be used effectively to reduce plate distortion and time between passes when controlling inter-pass temperature on mult-pass welds. The process is capable of producing x-ray quality welds with excellent mechanical properties.

Dual wire infeed laser welding machine - twin wire infeed laser welding machine, double wire infeed laser welding machine - tandem wire infeed laser welding machine

High efficiency dual wire feed laser welding machine, especially suitable for wide welds.

The Advantages of Dual Laser Welding at a Glance

- Big gap closing capacity

- Multi layers possible

- Wide welding gap filling capacity ( 2 x 1.6 mm wire = 2.5~3.0 mm gap filling capacity)

- Extremely high welding speeds

- Extremely high deposition rate

- Can be used on thin and thick sheets

- High potential for cost savings

- Easy to operate

- Two separate wire feeders but each wire can be controlled independently

- When not welding in dual welding mode, both wire feeders can be used to be prepared for a differeent material (ex stainless steel on 1 and alumiunium on 2) so that the changeover from one material to another is VERY short.

Multiwire laser welding for increased gap bridgability

PhotonWeld Laser welding: Filling the gaps

Double wire laser welding, also known as laser beam welding with two wires, is a laser welding process in which two wires are melted simultaneously using a laser beam to join two metal parts. This method is commonly used in welding applications that require high productivity, speed, and quality or especially when a big gap between the components must be filled. with double wire feeding the Photonweld laser welding machine can fill easily a gap of 2 mm.

The process of double wire laser welding is characterized by a high power density laser beam that is focused on the welding area, creating a small and intense heat source. This high heat input enables the simultaneous melting of two wires, which then join together to form a strong bond.

The advantages of double wire laser welding include increased welding speed, improved welding quality, and reduced material waste. The high speed of the laser beam allows for fast and efficient welding, which can significantly increase productivity. Additionally, the precise control of the laser beam allows for precise and accurate welding, which leads to improved welding quality and reduced defects.

However, there are also some challenges associated with double wire laser welding. One challenge is the selection of appropriate welding parameters, such as laser power, welding speed, and wire feed rate. Another challenge is the need for a higher level of technical expertise to operate the laser welding equipment and control the welding process.

Twin Wire Feed Means a Greater Ability to Fill the Wire and to Weld Wider Seams. According to Our Test Data, if You Use a Single-feed Laser Welding Machine Can Only Weld a Maximum of 1.5-1.8mm Seams. However, with a Double-feed Laser Welding Machine, a 3-4mm Wide Seam Can Be Welded.

Twin Wire Feed Also Means That Thicker Materials Can Be Welded. This is Because More Wire Filling in the Welding Process Makes the Welding Joint More Stronger,Stable, and Reliable.

In conclusion, double wire laser welding is a highly efficient and effective welding process that has many advantages over traditional welding methods. However, it requires specialized equipment and expertise to achieve optimal results.

Twin wire laser welding system on PhotonWeld A-Pro

Dual wire laser welding system on PhotonWeld A-Pro