Laser Filter Windows

Laser Safety Viewing Windows - Laser Filter Windows

Laser viewing windows enable you to see inside an enclosure while stopping the laser radiation from coming out, thus providing protection with the minimum of inconvenience. These viewing windows are available for a wide variety of different types of lasers and can be made of either high tech plastic or mineral glass

In High Tech plastics: Cost-effective, lightweight protection in large sizes for low power lasers and diffuse reflections from high power lasers

We are able to supply any of these filters in custom sizes up to the largest size available (typically 1280 x 1000 mm). We are also able to supply them machined to an engineering drawing if desired, ready for assembly into your system. This is cost effective for larger numbers of windows or where there is an ongoing requirement.

Laser Safety windows - Laser Safety protection windows

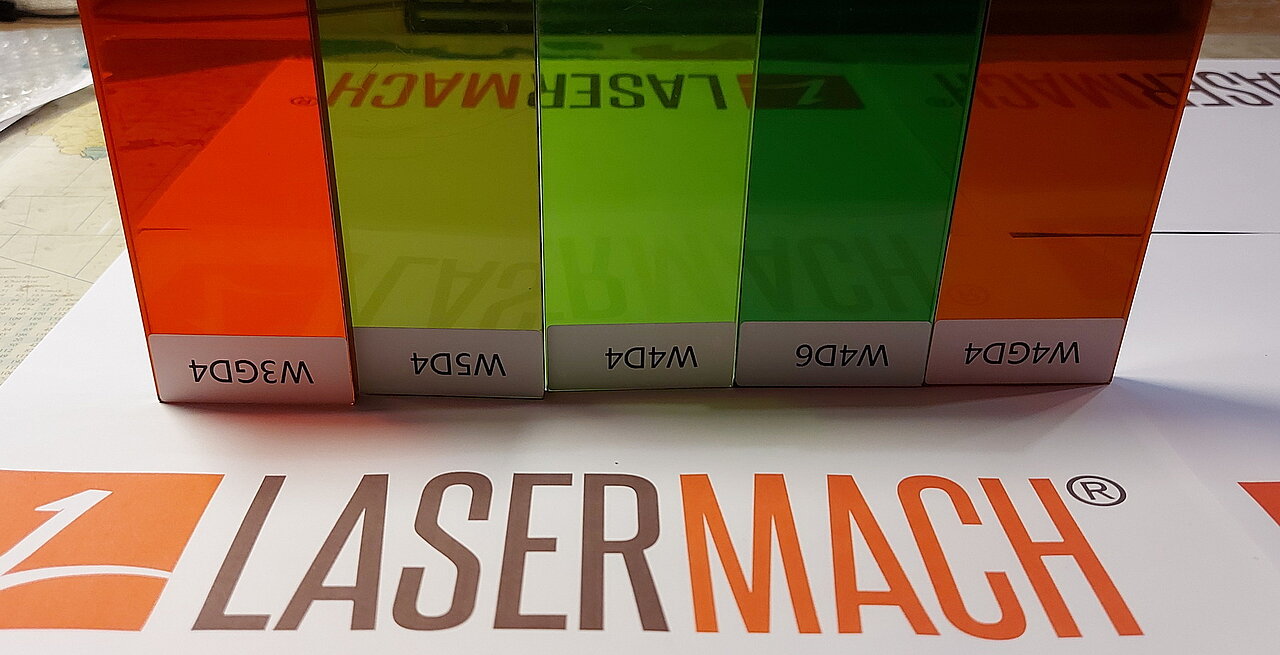

Acrylic fully coloured laser protection windows in different absorbtion classes

The technological development in the field of absorbing dyes during the last years results in more and more resistant plastic/acrylic laser protection windows. In the past the plastic windows were commonly used against stray radiation. Meanwhile some plastic laser protection windows achieve a laser resistances comparable or even beter to that of mineral glass windows. A representative example therefor is the laser protection window protection+8 with 5mm thickness. Between 1030nm-1400nm it achieves with OD8+ and a 10 seconds test time an EN 207 protection level of D LB7 + IRM LB8.

An essential advantage regarding plastic/acrylic laser protection windows is the availability of much larger sheets and the lower weight. The main application range is for our windows laser welding enclosures. For such applications lasermach is offering a large variety of different acrylic laser protection windows depending on the power, wavelength and application.

Windows are not considered to be PPE and can be marked with their optical density OD only, but as a standard, most materials do have a certification acc. to EN207 and acc. DIN EN 60825-4 and indicate LB ratings.

Highlights

- Low weight, good optical properties

- Available for many laser and laser combinations

- Most window filter certified acc. EN207 with 5s and 10s

- Dimensions up to 1240mm x 1000mm for all absorption classes

- Some filters available in 3mm, 5mm or 6mm thickness

Marking the PhotonSafe laser safety windows according to EN 60825-4

Based on the standard DIN EN 60825-1:2008 for laser protection, a laser system must be designed and installed in such a way, that harmful radiation is not accessible under all circumstances. This means, that the maximum permissible irradiance levels for eyes and skin must not be exceeded outside a laser protection system or cabin. According to the Machinery Directive 2006/42/EC, the enclosure, protective walls and windows of a laser system are also considered as safety components.

So far, most laser protection filters, which are also used as a laser safety window, received an EC type examination certificate (CE certificate) based on the standard for laser safety eye-wear EN 207. With the re-evaluation of the Directive on Personal Protective Equipment (PPE) to EU Regulation 2016/425, however, new requirements for all PPE products, such as information on manufacturing and expiration date as well as on storage or service life time have to be provided by the manufacturer within the product instructions.

Since a laser safety window does not represent a PPE, in future the CE certification of the laser safety windows from Lasermach will be based on the standard EN 60825-4 of the Machinery Directive. Due to significantly different test conditions, a direct comparability of differently certified products is basically impossible. The differences between the various test standards are briefly summarized below.

EN 207; EN 208 - Laser eye protection. Through the approval of an independent certifier, laser protection filters made of glass or plastic material for Personal Protective Equipment (such as laser safety eyewear) obtain an EC type examination certificate (CE certificate) based on EN 207 or EN 208 test standards. The specified irradiation time is 5 seconds (or 50 pulses) with a beam diameter D63 of 1 mm. If a material passes that test successfully, a certificate will be issued with LB protection levels (OD levels) for the tested wavelength or wavelength ranges and laser modes (DIRM). This certificate is valid 5 years.

EN 12254 - Screens for laser working places. This test standard applies to temporary, mobile and supervised laser protection setups like curtains or foldable walls up to a maximum average power of 100 W or a single pulse energy of 30 J. The specified irradiation time is 100 seconds with a beam diameter D63 of 1mm. If a material passes that test successfully, a certificate is issued with AB protection levels for the tested wavelength or wavelength ranges and laser modes (DIRM). This certificate is valid 5 years. However, laser enclosures and housings (as part of the laser system) are not part of the scope of this standard. An inspection according to EN 12254 alone does not justify putting a CE mark onto the product.

EN 60825-1; 60825-4 - Safety of laser products. The standard DIN EN 60825-4: 2011 defines the requirements for protective walls of laser cabins. For this purpose, three different test conditions have been defined: fully automatic operation (T1 / 30,000 s), partially supervised operation (T2 / 100 s) and permanently supervised operation (T3 / 10 s). The lifetime of the material correlates with the protective exposure limit (PEL), i.e. the power density and the maximum time that a protective housing may be exposed to a direct laser hit, without causing any danger outside the housing. To determine the protective exposure limit laser stress tests are specified, which are carried out with a resulting spot diameter (D86) typically at 3 times the focal length. This irradiation test authorizes the issuing of the CE mark for the tested wavelength or wavelength ranges by an expert or approved certifier or as part of the manufacturer's declaration by the producer.

CE marking of PhotonSafe safety windows, which is not a mandatory requirement, always comes with a reference to the test standard EN 60825-4 in its latest version. In order to offer more information for easier evaluation and comparability, additionally, LB- and AB safety levels of the specific product will be provided on separate labels. The user can then attach those labels to the machine housing or to the system documentation. As an option, lasermach will still be able to mark those additional specs directly onto the laser safety window.