Protect your employees and equipment with high-quality laser enclosures

If you have employees working with lasers, you know that safety is a top priority. One key component to maintaining a safe workspace is investing in high-quality laser enclosures. These enclosures provide a protective barrier around your equipment, keeping your employees safe from harmful radiation and stray beams. Not only do they offer crucial protection, but they also help prolong the lifespan of your laser equipment by preventing dust and debris from accumulating on sensitive components. By investing in laser enclosures from PhotonSafe, you’re making a smart choice that prioritizes the health and safety of your employees, as well as the longevity of your equipment.

Why do I need a laser enclosure?

Safety precautions when working with class 4 lasers cannot be understated.

Laser welding is a fast growing leading edge technology in modern manufacturing which offers fast production, low running costs, minimal setup, ease of use, excellent energy efficiency, minimal use of consumables, minimal post processing requirements and exceptional weld quality of both similar and dissimilar metals.

However, the use of lasers can also pose significant safety risks to operators and other personnel in the vicinity of the welding process. An enclosure provides a controlled and isolated environment for the laser welding process, minimizing the risk of exposure to laser radiation, hazardous fumes and sparks. This significantly improves the safety of the personnel working around the welding area and prevents accidents or injuries.

It is your responsibility to ensure that any class 4 laser equipment is operated in a safe way!

The safest way to protect uninvolved people from the invisible risks of laser radiation is to install an enclosed laser cabin and create a 'laser controlled area'. The installation of an enclosure for laser welding is a critical safety measure to protect people and equipment from potential hazards. This will not only help protect from the risks of laser radiation, but it will also help contain harmful gases and tiny, cancerous, combustible particles that arise from the welding process.

When using a Class 4 laser welder it is imperative that you use a suitable Class 4 enclosure.

Without taking into account the type of application, the best way to safeguard a class 4 laser environment might be to enclose the whole area on a large scale within a cabin. This kind of cabin solution is frequently used, particularly in the case of laser power ratings in the multi-kW range (as used in laser welding). Using a PhotonSafe laser cabin will help create a laser controlled area and comply with safety regulations and standards which must not be overlooked.

Protection at laser Welding

PhotonSafe : our support products in Laser Welding Safety

Laser Wall Partitions

PhotonSafe® laser safety barrier

An open design that utilizes existing lighting and sprinkler systems.

Our prefabricated wall systems can be arranged in a variety of configurations in create laser workstations. Walls can extend from floor-to-ceiling or an open design that can utilize existing lighting and sprinkler systems.

The PhotonSafe® laser safety barrier materials are ideally suited for enclosing laser welding systems of medium to High power.

- The laser protection systems are safe, flexible and individual

- The barriers are certified according to EN 60825-4

Our Standard Laser safety rooms

A fully enclosed modular laser room in different dimensions with multiple roof and ceiling options.

Laser Rooms

Fully enclosed (Option)

Standard Plug-and-Play ready made Laser welding Safety rooms

Our prefabricated wall and ceiling systems can be used to create fully enclosed laser welding rooms.

Our standard range of PhotonSafe laser welding enclosures/rooms come in sizes starting from

3m x 2m up to 6m x 6m and have sliding and hinged door variants.

The PhotonSafe modular system of the laser welding cell allows an individual configuration of the cell in the standard grid.

Laser Safety Welding Cabins

PhotonSafe Laser Welding protection castle

Laser Safety Cabins

Modular enclosure design

Customized laser enclosures for your company

The Laser Cabin is a cutting-edge, modular enclosure designed to enhance precision, safety, and efficiency in your Laser welding applications. If you require greater environmental control, our wall and ceiling systems can also establish a suitable environment for your laser or robotic process by helping you to manage temperature, humidity, and energy efficiency. Specifically designed for: laser welding.

The construction takes place according to your specifications and the structural conditions at the assembly site.

Download all info and pricing on our Photonsafe Laser welding protection Cabins

Certified Laser welding protection Cabins- pricing of laser Welding protection Cabins

PhotonSafe © Industrial Laser Welding protection products

PhotonSafe © Laser Enclosures will give you a cost effective and robust solution that has the modularity to allow future expansion.

Take advantage of the latest laser welding technologies whilst protecting your employees from the health risks with one of our PhotonSafe laser welding enclosures solutions!

Why use a laser welding enclosure around a class 4 handheld laser welder?

A laser welding enclosure creates a safe enviroment

When it comes to safety and efficiency, using a laser welding enclosure around a Class 4 handheld laser welder is a must. A laser enclosure is designed to contain laser radiation and prevent it from reflecting off of any surfaces, making the workspace much safer for everyone.

A laser enclosure provides an environment that has been specifically designed to contain and control the use of laser radiation. This includes features such as warning signs, safety interlocks, fume extraction, and shielding to ensure the protection of personnel and the surrounding environment. These areas are designed to minimise the risk of potential hazards associated with laser radiation, such as fire and burns to the skin/eyes.

Access to a laser enclosure should be limited only to those authorised and qualified to ensure the safety of all involved. Lasers can be dangerous and can cause permanent eye damage or even blindness, as well as skin and clothing burns. Unauthorised personnel, who may not be aware of the laser's potential hazards, may inadvertently introduce safety risks, such as forgetting to turn the laser off or tampering with the enclosure or its contents. Additionally, qualified personnel are better able to identify potential safety issues, and know how to properly operate, maintain, and repair the laser.

As the laser welding enclosure provides a localised area to work in extraction must be considered. Extraction is used on a laser welding enclosure to remove fumes, dust, and smoke from the welding process. This helps ensure the safety of personnel and a clean, organized working environment. Additionally, extraction helps ensure the welding process’s accuracy by removing any particles that could interfere with the laser beam.

One of the most immediate risks of not using proper extraction is respiratory health effects. When welding with a laser, hazardous gases and particles are released into the air, and without effective extraction, these contaminants can easily be inhaled. Over time, this can lead to serious respiratory problems like asthma, bronchitis, and even cancer.

Lasermach can quickly design, construct and install modular, Class 1, room-sized enclosures that meet global laser safety requirements (as outlined in IEC 60825-4 Safety of Laser Products Part 4 – Laser Guards).

OUR PATENTED LASER PROTECTIVE WALL

INNOVATIVE PROTECTIVE WALL SYSTEM FOR LASER PROTECTIVE CABINS

Our patented PhotonSafe® protection Wall is an innovative material for the manufacture of passiv laser protection walls or complete laser protection cabins for higher laser outputs up to 5 kW.

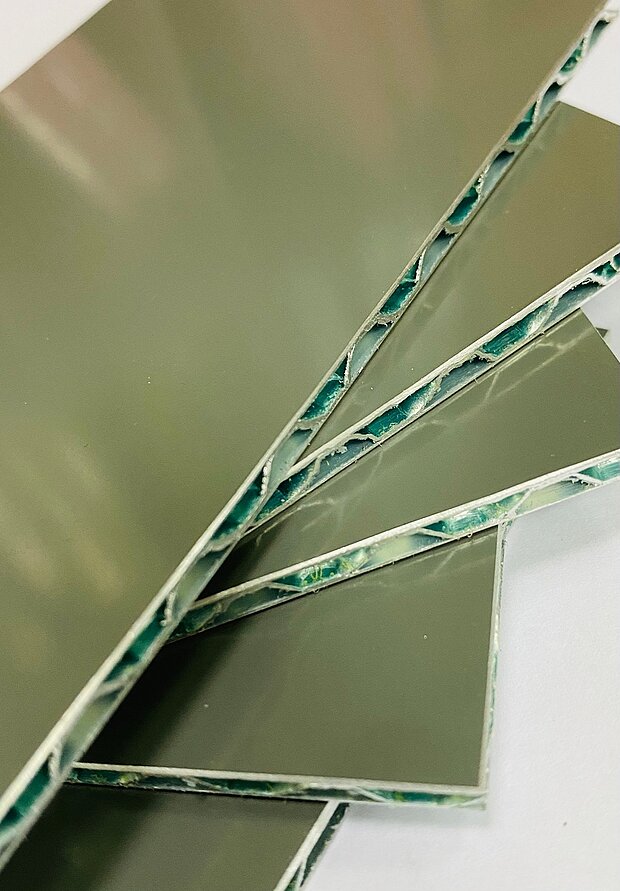

PhotonSafe Laser Safety Walls, Barriers, Ceilings are Constructed of the patented aluminium panel “PhotonSafe Laser Shield 4005™” and aluminium frames.

Our protection walls are designed for the protection of kilowatt-level laser, especially for high power laser welding and laser cleaning, laser processing workshop and laser device, with its characteristics of high level protection and flexibility.

The material is characterised by low grammage, high inherent stiffness and very high resistance to laser radiation (satisfies a permissible exposure limit (PEL) of 158 MW/m2 according to the current test standard DIN/EN 60 825-4. The PhotonSafe® protection wall meets these requirements for the wavelength range of 850-1100nm and thus covers diode and solid-state lasers (disk and fibre lasers).

The PhotonSafe special laser Shield 4005 impact plates shields successfully the heaviest laser power for a much longer time than the others and got patent as super safe invention in 2022.

This makes it far superior to all conventional passive protective wall systems currently available on the market. The protective housings designed by us always meet the requirements of laser class 1.

We supply you with this innovative, cost-effective material as sheet material, as a blank, asa shield or as a complete laser cabin, equipped according to your specification, with or without final assembly.

This were the first laser protective laser impact plates with independent intellectual property rights.

PhotonSAFE®: Non Conbustable Laser Welding rooms

All materials used are all "non-combustible" as they received all an Euroclass A1 rating under BS EN 13501-1

A1 materials are completely non-combustible while A2 materials have very limited combustibility. While A1 materials have no contribution to fire, A2 materials have limited contribution to fire. Stringent tests must be passed in order for construction products to reach a Class A rating. As above, A1 rated products do not require additional safety tests given they are completely non-combustible. Examples of these materials include aluminium, steel, natural stone, concrete and porcelain.

Lasermach’s design allows for easy installation as our lightweight panels with fire ratings Class A1 come in 800-1000-1200 mm width and are assembled on site. Installing this way minimizes the need for riggers and costly equipment needed to install full wall panels.

PhotonSAFE® is the solution for providing an enclosure for light based welding applications, and is available in standard and customized versions. Lighting, bottle securement, fume extraction, power management, and table integration are all features available on the PhotonSAFE welding booth system. Interlock protection is standard on the PhotonSAFE and can be integrated with the Photonweld laser welding (or other brands) machines.