NOW available: Patented Modular PhotonSafe Laser Welding Safety Rooms

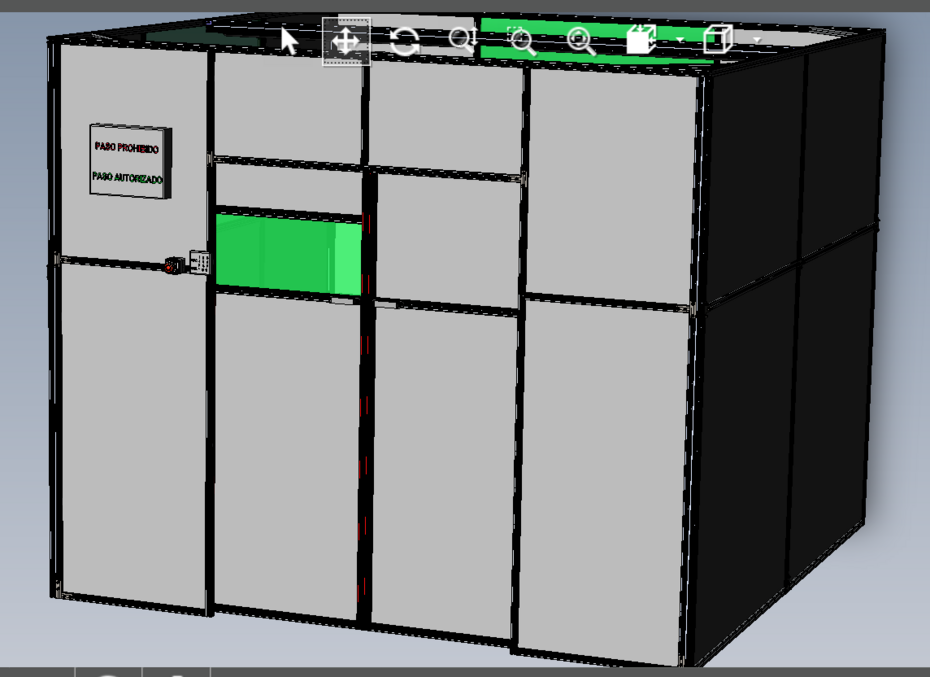

PhotonSafe Laser Castle comprises of laser safety window, door, interlock system, laser warning signs and video monitoring system, etc

Our Modular system for maximum flexibility with laser welding safety

STANDARD RANGE PhotonSafe modular laser welding safety rooms

- Our standard range of PhotonSafe laser welding enclosures come in sizes starting from 3m x 3m up to 8m x 4m and have single or double sliding or hinged door variants.

- They each come with “plug and play” electronics including, lighting, power distribution, laser-on warning light, and door interlock.

- They are light-tight around the perimeter and have the option for a roof

- One Laser protection viewing window comes as a standard. More windows or a CCTV system can be added as option.

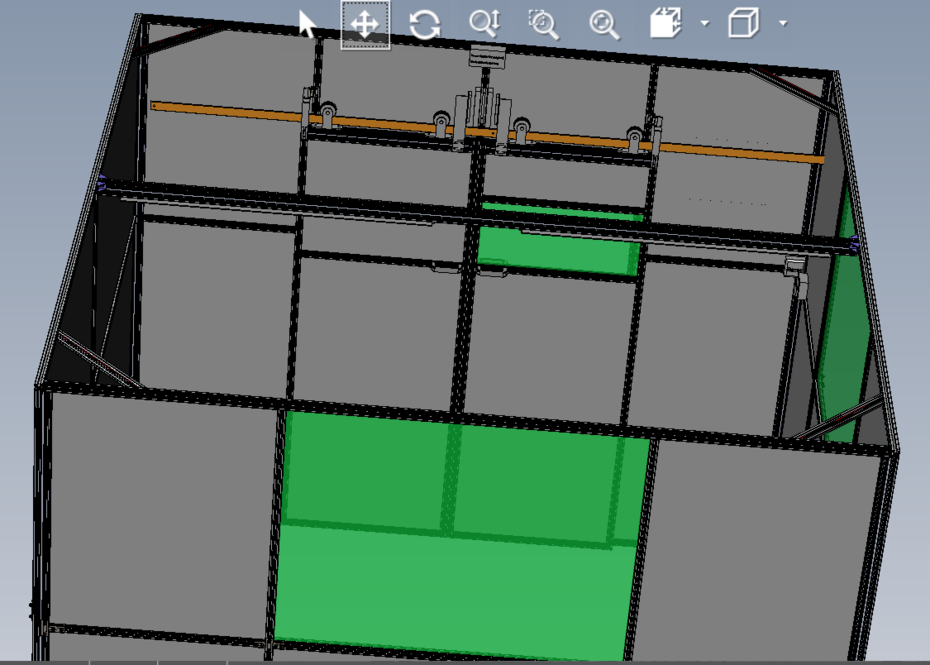

- If necessary, the laser welding cell can also be equipped with a roof made of aluminium patented frustum structure panels.

The PhotonSafe modular system of the laser welding cell allows an individual configuration of the cell in the standard grid. Of course, special solutions can also be implemented at an additional cost.

Custom laser protection cabins

Our tailor-made laser protection cabins are specially designed to protect you against your laser sources while being certified according to the EN 60825-4 standard.

Our company Lasermach with our own engineering team and its various partners and tertiary installers, offers a study, design, conception and installation of tailor-made laser protection cabins.

Our different laser protection cabins are manufactured according to your technical specifications. We can also personalize the enclosure by installing door(s), laser protection windows and/or airlocks, for example.

For any request, do not hesitate to contact us via email or telephone. +32 56 333 240

PhotonSafe: MODULAR LASER-WELDING ROOMS

JOINING TOGETHER PRECISION, SAFETY AND CONVENIENCE at an affordable price

Where Safety and Functionality Connect

Laser welding is a welding technology that connects multiple pieces of metal through the application of lasers. It’s commonly applied in automotive plants and factories and is an incredibly helpful and convenient resource for connecting prefabricated parts under extreme temperature restrictions. It also requires a safe, comfortable, controlled, and condition-appropriate environment to help ensure it’s done correctly, minimize distortion, and minimize the risk of accidents to your employees. Lasermach has specialized experience developing modular laser-welding rooms to help you keep your employees safe while maintaining the right conditions for optimum laser-cutting performance. Contact a member of our team to learn more about our laser-cutting room options.

Specialized Benefits and Requirements of Laser-Welding Rooms and Enclosures

Safe and conducive modular laser-welding rooms require a few key factors that distinguish them from other structures and construction environments. This is due almost entirely to the high temperatures required for the welding process and the potential risks associated with them.

Full room laser enclosures create a complete laser-safe environment:

- Special glass windows rated to specific welding equipment.

- Specialized high-performance HVAC systems that can accommodate heat loads produced by laser welders.

- Specially designed entry doors with safety interlocks that work in conjunction with the laser welder to halt welding immediately upon opening.

- Safety alert warning lights visually warn room occupants and those in nearby proximity that the laser welder is in use.

- Light switches for the laser room are on the outside wall by the door, so control is reserved to entry and exit.

Laser enclosures are needed to house laser workstations, which serve as a protective barrier for personnel outside of the enclosures from the laser process. To meet requirements, options include:

- Walls made of fire retardant materials

- An open design that could utilize existing lighting and sprinkler systems

- Laser safety glass windows where required

Traditional vinyl gypsum modular wall panels and standard LED lights can still be used. LASERMACH modular laser-welding rooms can be customized to fit equipment and footprint allotted for the process, no matter what the size and expansion plans of your facility may be.

Testing Your Metal: The Modular Laser-Welding Design and Construction Process

When designing and constructing a modular laser-welding room, it’s important to keep safety top of mind. It’s important that your room is tested in accordance with IEC 60825-4:2009-06, which measures the requirements for temporary or permanent laser guards that enclose the process zone of a laser processing machine. Other critical safety and performance-related components include floors that can accommodate adequate welding equipment and personnel weight load and tightly sealed entry and exit ways to minimize the escape of smoke and laser light.

LASERMACH’s modular laser-welding enclosures offer:

- Complete customization to fit all sizes, expansions, and utility needs.

- Complete compliance with all OSHA regulations.

- Quick-ship capabilities to be delivered in just two weeks.

- Customized design options.

- Turnkey safe installation including permitting, electrical, fire protection, flooring, HVAC, and erection of the building.

Our team offers turn-key support to ensure a hassle-free process.

Let Us Help You Build Your Next Laser-Welding Room

Contact a member of the team today for a prompt response: +32 56 333 240

Download all info and pricing on our Photonsafe Laser welding cabins

Certified Laser welding protection Cabins- pricing of laser Welding protection Cabins - modular cabins on demand