Our 21st Century major Challenges :

We face two major challenges in the 21st century:

digital transformation and ecological transition.

Ecological transition is an essential objective for humanity.

Digital technology is one of the greatest transformative forces of our time.

Lasermach is continuously working to use its innovative optical technology to develop breakthrough products while minimizing its environmental impact. Manufacturing Industry is requested to operate economically. In terms of sustainability this means to make responsible use of resources according to the economic principle.

Instead of “maximum profit from minimum capital” the term should be superseded by “maximum results (economically and ecologically) from minimum resources”.

The necessity of efficient application of resources advances further into the focus of corporative tasks in economy, research and politics. Within the framework of manufacturing the question has to be raised which possibilities exist to reduce the input ofresources as well as the emissions.

Against the background of statements like “. . . lasers are your best friend for a greener planet!” the ecological impact of lasers in materials processing fulfils most of the conditions for resource and energy efficient manufacturing due to it's specific characteristics like concentrated energy input and high thermal efficiencies.

I

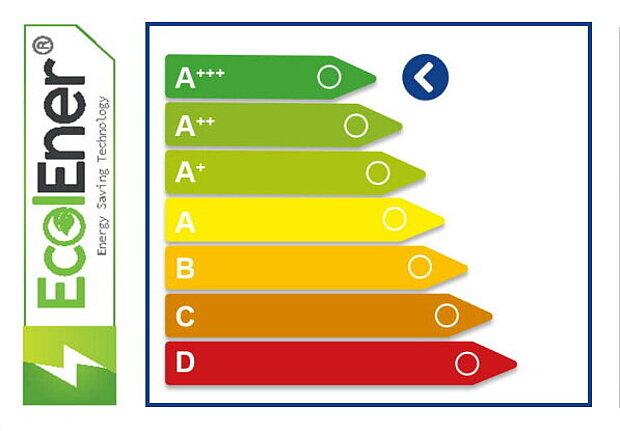

PhotonWeld© with EcolEner© Technology

The Best and most ecological LaserWelder on the market today

Our proven EcoLener © family of very high effiencent lasers is a new generation of kW class high brightness Ytterbium fiber lasers with record wall-plug efficiency of almost 50%. Lasermach's EcoLener series offers a new, unparalled level of reliability. The EcoLener series is perfectly suited for applications that cannot tolerate any downtime or service intervention. PhotonWELD laser Welding Machines with EcoLener high Efficient Laser Sources mark another ‘first’ for the company, in providing the highest efficiency, most reliable industrial lasers available.

PhotonWELD © enhances Lasermach’s corporate sustainability programs as it is designed to enable a more environmentally friendly welding process offering very low electric consumption, low fume generation, low noise operation, and a drastic reduction of consumables, post processing clean up and reduced scrap disposal.

Rethinking Welding

For a greener tomorrow

Rethinking Welding for a Greener Tomorrow

Currently, the metal welding sector accounts also for of part of global carbon emissions. According to experts, this number is expected to increase dramatically by 2030, which leaves a clear incentive for the industry to deliver significant reductions in emissions in the years to come.

Manufacturing Industry is requested to operate economically. In terms of sustainability this means to make responsible use of resources according to the economic principle.

Instead of

“maximum profit from minimum capital”

the term should be superseded by

“maximum results (economically and ecologically) from minimum resources”.

The necessity of efficient application of resources advances further into the focus of corporative tasks in economy, research and politics. Within the framework of manufacturing the question has to be raised which possibilities exist to reduce the input ofresources as well as the emissions.

Against the background of statements like “. . . lasers are your best friend for a greener planet!” the ecological impact of lasers in materials processing fulfils most of the conditions for resource and energy efficient manufacturing due to it's specific characteristics like concentrated energy input and high thermal efficiencies.

With our New PhotonWeld© High Efficient Laser Welding Machine with the revolutionary EcolEner® Energy Saving Technology, we are able to increase the Wall Plug Efficiency to levels over 50%, which is an energy reduction of over 30% compared to normal laser welding machines and till 90% compared to conventional arc welding machines.

PhotonWeld: a World Leader in Green Welding Solutions

An Industry-Leading Decarbonization Strategy for the welding industry Handheld laser welding : drastic reduction of your Carbon Footprint

PhotonWeld helps to save our Planet

Worldwide consumption and production — a driving force of the global economy — rest on the use of the natural environment and resources in a way that continues to have destructive impacts on the planet.

Economic and social progress over the last century has been accompanied by environmental degradation that is endangering the very systems on which our future development — indeed, our very survival — depends.

A few facts and figures:

Each year, an estimated one third of all food produced – equivalent to 1.3 billion tonnes worth around $1 trillion – ends up rotting in the bins of consumers and retailers, or spoiling due to poor transportation and harvesting practices.

If people worldwide switched to energy efficient light bulbs the world would save US$120 billion annually.

Should the global population reach 9.6 billion by 2050, the equivalent of almost three planets could be required to provide the natural resources needed to sustain current lifestyles.

Sustainable consumption and production is about doing more and better with less. Sustainable production will also contribute substantially to poverty alleviation and the transition towards low-carbon and green economies. It is also about decoupling economic growth from environmental degradation, increasing resource efficiency and promoting sustainable lifestyles.

This is Where EcoLener technology comes in and does much more with much less energy than any other laser source!